Electrodeionization system (EDI water system) is an advanced technology that removes most impurities in water, creating High purity water sources of up to 99.9%, ensuring safety for users. In the field of wet towel production in particular and the production of skin care products in general, water plays a vital role in determining the quality of products, so it is essential for businesses to invest in a sound water filtration system. absolutely necessary. Below is a detailed share of today’s leading water filtration technology.

Learn more: Industrial reverse osmosis systems (RO)| Pros & cons

EDI (Electrodeionization) technology means Vietnamese – “electrodeization”. The mechanism of action of this scientific invention is through electrolysis of water, splitting H2O water molecules into H+ and OH- ions, removing ions – especially mineral ions (such as sodium, calcium, copper cations… ) and anions (such as chloride, nitrate, etc.). These ions are closely related to atopic dermatitis problems. This is considered the most modern water purification system used for water treatment in manufacturing.

EDI water filtration system – today’s most modern water purification technology

Below is a comparison table of some popular water purification technologies used in wet wipes production to help you have an objective view and make the right choice. :

| UF filtration technology | RO filtration technology | EDI filtration technology | |

| Mechanism | Uses pressure to remove large molecules from water, precisely: purified water, mineral salts and ionic molecules smaller than 0.1- 0.001 microns. Beneficial ions, minerals and salts are retained | Applying the principle of reverse osmosis in medicine, with extremely small filter membranes of only 0.1 – 0.5 nanometers, creating 99% pure water. | Using water electrolysis splits H2O water molecules into H+ and OH- ions, which helps to remove ions – especially mineral ions (such as sodium cations, calcium, copper …) and anions (such as chloride, nitrate …). These ions are closely related to atopic dermatitis problems. |

| Generated water | Purified

Does not entirely remove solids, bacteria, impurities,… |

Purified water

Completely removes harmful bacteria, impurities, fungi, remaining 0.2 – 2.0% of the impurities. A single ion with a very small size (small 0.1 – 0.5 nanometer). This outlet water does not retain beneficial minerals. |

99.9% ultra-pure water

Completely removes bacteria, impurities, dirty fungi, solids and ions. This outlet water retains beneficial minerals. |

| Advantages |

|

|

|

| Limitations |

|

|

The investment cost for the EDI system is high. |

| Application in production |

|

|

|

After the filtration process through the RO and EDI systems, the water is removed from impurities, microorganisms and ions.

Thus, through the above analysis table, you can easily see that the RO and EDI water purification systems provide a water source. Quality water used for production by these systems almost completely eliminates harmful bacteria and impurities that can affect the quality of the product.

If you are a business with production purposes related to the food, beverage, or cosmetic industry, aiming for high quality, which can be used even by subjects with sensitive skin, you should choose the system first. EDI system because this technology creates 99.9% ultra-pure water and also retains beneficial minerals for healthy skin or joints.

Enterprises dealing in pharmaceutical, cosmetic, and food products should use advanced water filtration systems such as EDI

EDI water filtration systems are widely used in developed countries. The country has very high product quality standards. Moreover, manufacturing businesses need to invest in a quality water filtration system because using pure water will help the nutrients in the product penetrate more efficiently, and the skin care effect of the product will be better. This helps to improve product quality and increase consumer confidence in the products your business offers.

In particular, water is an indispensable ingredient in production, acting as a “solvent”, helping substances easily penetrate the fabric. The EDI water filtration system helps businesses own super clean water to create wet wipes with safety standards that meet regulatory standards.

EDI water is applied in the production of cold towels to create high-quality and safe products

Read now:

The EDI filtration system combines reverse osmosis (RO filtration) and demineralization to produce high purity and quality water. Usually, a system is composed of 1 or more modules, in each module includes the following 5 components: Ion exchange resin beads, 2 ion exchange membranes and 2 electrodes.

1 – Resin beads (ion exchange resins):

These are plastic particles that are insoluble in water, they contain ions that are easily exchanged with other ions in the solution as the solution flows through the exchange column. This ion exchange process takes place rapidly, without changing the physical properties of the exchange particles. Ion exchange resins are used in water purification systems to soften water or remove unnecessary minerals.

In addition, the EDI filter system also contains 2 main compartments:

The EDI water purification process uses an electric current to pass ions through a membrane and resin to filter out all impurities. Accordingly, water will enter module, which acts as an ion exchange medium. This means that an electric field is applied perpendicular to the flow of the liquid, helping the impurities to move through the area of the resin and film. Unwanted particles are collected into concentrated streams that can exit the system or be recycled. What is left after the process is complete is deionized water that can be used directly or sent to undergo another round of purification.

EDI Water Purification System uses electric current to pass icon through resin and membrane to remove impurities

Through the EDI water filtration system, contaminants are ionized and successfully removed, including ammonia, boron, silica, residual salts and carbon dioxide – some of which have the potential to affect the respiratory, cardiovascular and skin systems. This method produces not only pure water but also offers many additional benefits when compared to other types of processes, as shared above. One of the most important is that impurities are removed from the system, rather than accumulating in the resin or film, meaning a single EDI unit can be used continuously for many years before needing to be replaced. This helps businesses save money in the long run.

The Electrodeionization system works through the phenomenon of water electrolysis, separating H2O water molecules into H+ and OH- ions, including 3 stages as follows: :

Stage 1: Deionization

Water containing many cations, Ca2+ (Calcium) and Mg2+ (Magnesium) (over 300mg/liter) is called hard water. In fact, water always contains essential mineral components for the body, such as calcium, magnesium, iron, phosphorus,… Calcium plays a vital role in the formation, development and strengthening of the vocal system. joints in the body. If calcium helps strengthen bones, magnesium helps fight the aging process of bones.

Discover more: 9 harmful ingredients in wet wipes & Label reading guide (latest updated)

Hard water contains concentrations of cations Ca2+ and Mg2+ exceeding the allowable levels.

Standardized water ensures that the concentration of these trace elements is at the allowable level (under 300mg/liter). When exceeding this threshold, water is called hard water and is more likely to cause harm to health: related diseases such as kidney stones, urinary stones, or blockage of the walls of arteries and veins due to the accumulation of limescale. In production, the use of hard water causes the formation of salt layers that accumulate on the surface of the device, thereby reducing the ability to conduct heat, or, more dangerously, causing system overload and fire.

Using hard water has the potential to cause harm to health, such as kidney stones, urinary stones.

Therefore, the treatment of hard water or the reduction and removal of Ca2+ (Calcium) and Mg2+ (Magnesium) cations is essential for the production and daily consumption.

At the first stage of the EDI water purification process, the positive cations and negative anions will be reduced through the H+ cation exchanger, removing the Ca2+ and Mg2+ cations. At the same time, OH- ion resin particles remove Cl-, NO3-… The result of ion exchange in water is that H+ ions and OH- ions will replace cations and anions, thereby creating pure water – water that no longer contains pollutants or substances that are harmful to the user’s skin and health.

The first stage of the EDI filtration process helps to remove positive cation ions and negative anions

Stage 2: Ion migration

Different from RO (DI) water purification systems, after the cation Resin and anions have replaced all H+ and OH-, they need to be regenerated with acid and caustic soda. When using an EDI system, the power source in the EDI system provides an electric current between the two terminals (cathode and anode) so that the ions cannot move to the electrode and accumulate in the concentrator cavity, then will be discharged.

Thus, after stage 2, it helps to classify and keep wastewater containing cations and anions to be removed at the concentration chamber.

Wastewater is kept in the concentrator and discharged after the 2nd stage of the EDI water purification stage.

Stage 3: Regeneration

Here, the EDI water purification system regenerates the current quickly without using chemicals. (acid and sulfur), this technology instead takes advantage of the current used throughout the EDI module. Thanks to the electric current, the water molecules into H+ and OH- ions dissociate, helping to regenerate continuously with the plastic beads.

After filtering through an EDI system device with high resistivity of up to 18 MΩ-cm, the output water meets the ultrapure water requirements for production fields.

The EDI filter system regenerates the water stream without the use of acids and caustic soda

Water is an extremely important ingredient in private label wipes manufacturer, helping dissolve and absorb substances well into the towel. As mentioned above, to ensure clean water is used in production, water must be treated with a filtration system to remove impurities and harmful bacteria. These filters such as RO, UF, EDI,… In particular, EDI water purification technology creates the safest and quality water source, especially prioritized for use in baby care products or other products. Subjects with sensitive skin.

EDI water purification technology is considered the most advanced technology today because the outstanding advantage of electrodeionization systems is that it does not need to use chemicals such as acids and caustic soda to regenerate. The water generated through the filter tank has a pH of about 4.5-5.5 lower than the tap water. This is also the ideal, suitable and safe pH for the skin to help support the protection of the skin’s acid cell membrane, prevent water loss and resist bacterial invasion. NICU – American organization specializing in neonatal care.

DHTI uses an EDI water purification system in the production of wet wipes to create an “ideal” water source that can be used even for sensitive skin

After being treated through the EDI filtration system, the water source will be “ultra-pure” water. “Ultrapure” water is water that contains only two components, Hydrogen and Oxygen, which do not exist in nature but must be treated by modern systems. They are so pure that they contain no electrolytes or minerals. Thus, wet wipes containing EDI water will ensure safety, not cause skin irritation, and help consumers feel secure to use. Besides, the water is removed impurities and nutrients in the towel, which is easily absorbed and increases the effectiveness of skincare.

Wet wipes containing water filtered by the EDI system will ensure safe and healthy skin.

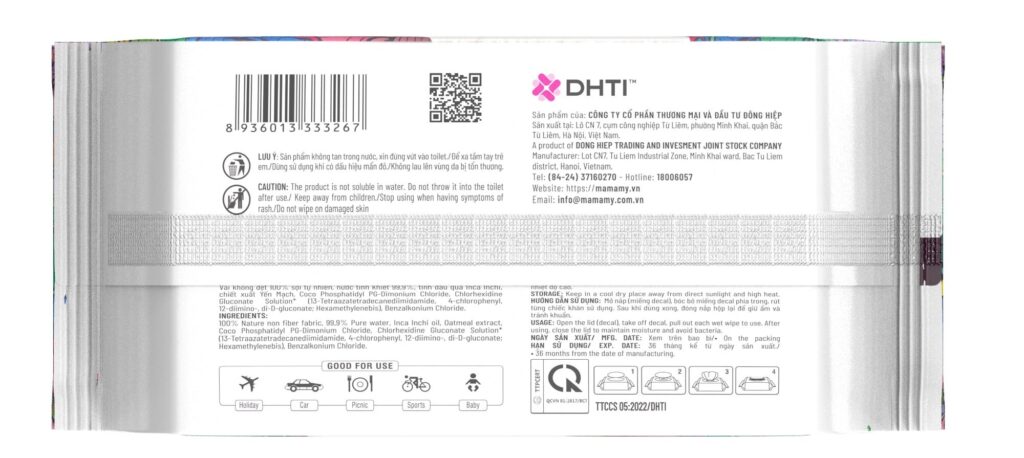

DHTI is also one of the wet wipes factory that has applied EDI technology in water treatment. Therefore, the water content in our wet wipes no longer contains bacteria, metals, or minerals that can affect consumers’ health.

A typical example of the quality of DHTI’s products is the Mamamy wet wipes line. This is a line of wet wipes for babies, so the safety of the baby’s skin and health is a top priority for parents. Understanding this, we always control the number of micro-minerals, micro-elements and heavy metals in the water source, completely removing impurities. Since then, safe and expensive nutrients have been quickly absorbed and skin care is more effective than wet wipes that are kept moist by normal hard water. That is the point that makes a remarkable difference in the quality of Mamamy premium wet wipes.

Dong Hiep Trading and Investment Joint Stock Company:

Mamamy wet wipes from DHTI manufacturer use ultra-pure water that is filtered through the EDI system

Mamamy wet wipes list contains ultra-pure water

The Electrodeionization system is considered one of the most advanced technologies leading today. When applying this technology in the wet wipes production, businesses will contribute to ensuring better output, providing customers with quality and safe products.

>>>> Helpful information: