ODM wet wipes is the right choice for companies with limited resources in designing and manufacturing wet wipes for their unit. With the ODM method, you can easily own wet wipes under your brand name while still optimizing production time and costs. The article below can bring you a thorough understanding of how you can achieve it.

Learn more: Private label wipes manufacturer – “Make your own wet wipes” solution

1. ODM wet wipes manufacturing

As a global leader in wet wipes manufacturing, DHTI has over 23 years of experience in leading ODM services. Our wet wipes factory has a total area of 3,000 square meters, utilizing advanced technology and equipment. Therefore, our production capacity can be gained up to 280 pieces per minute, covering a wide range of applications, including baby care, personal care, hygiene, and cleaning,… to meet the specific needs of our clients.

All of our wet wipes ODM are manufactured in accordance with international standards (SGS, FDA, GMP,…), with ISO 9001:2015 certificated for our factory and production process.

With years of experience in this industry, we have built long-term partnerships with many large brands around the world, from North America, Europe, Asia,…

Our ODM services include but are not limited:

- Wet wipe contract manufacturing

- Private label wet wipes manufacturing

- White label wet wipes manufacturing

Read now: OEM wet wipes method – All things wholesalers need to know

2. Our wet wipes ODM products

Currently, DHTI wet wipes manufacturer produces various types of ODM wet wipes. The company’s products include:

- ODM baby wet wipes.

- ODM personal care wet wipes.

- ODM antibacterial and disinfectant wet wipes.

- ODM restaurant and hotel wipes

- ODM airline’s wet wipes.

If you have any needs for wet wipes manufacturing, we fulfill them and exceed your expectations. Contact us today for more details:

Dong Hiep Trading and Investment Joint Stock Company:

- Representative office: 69B Thuy Khue, Thuy Khue Ward, Tay Ho District, Hanoi City.

- Factory address: Lot CN7, Tu Liem Industrial Cluster, Minh Khai Ward, Bac Tu Liem District, Hanoi.

- Hotline: (84-24).3716.0270.

- Website: https://dhti.vn/en/

Discover more: Wet wipes manufacturing cost | Price of each machine

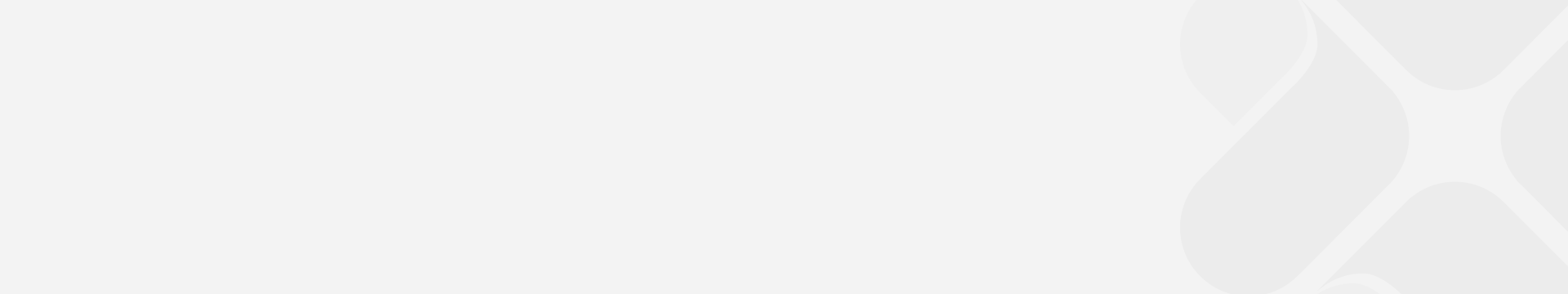

3. ODM wet wipes production process

Step 1: Submit request – Consultants:

After you place your order, we will contact you to determine what type of product you anticipate and what aspects are important to your business, such as the product type, product users, product design,… amount of resources that firms are prepared to expend, and more. Understanding these aspects is crucial for developing the optimal solution.

When we gather enough information and understand your needs, our team of experts will conduct research to determine the best production option. As a next step, we’ll arrange an appointment so that you can come see our line in action – and get a clear understanding of how your product will be manufactured.

Step 2. Direct visit to the factory:

As mentioned earlier, you will be invited to visit our wet wipes factory in Hanoi (specific address: Lot CN7, Tu Liem Industrial Cluster, Minh Khai Ward, Bac Tu Liem District, Hanoi).

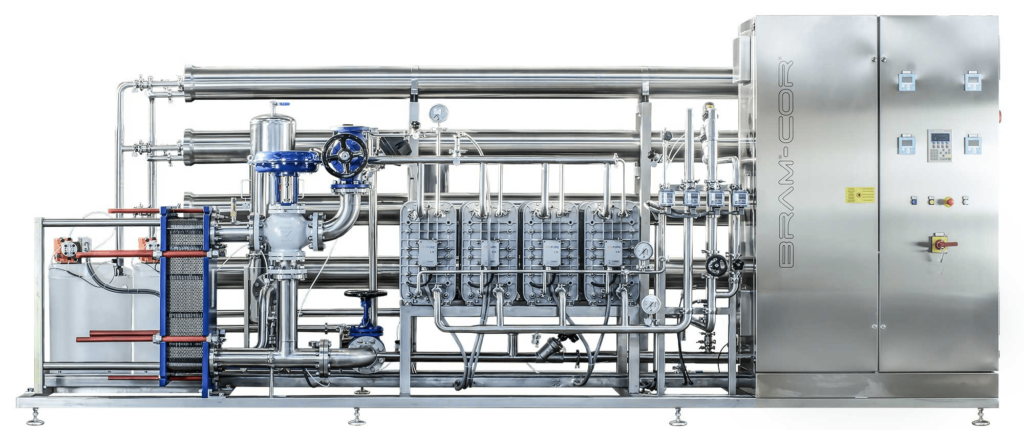

Before entering the production area, you must wear sanitized clothing and safety gear. Our staff will also explain how to use these items properly to ensure that you follow the right procedure. This is required to ensure the production environment is sanitary and free of hazardous pollutants, fungi, and microorganisms.

To maintain a sanitary atmosphere in the production area, all workers will be properly sanitized before and after each shift, and each machine and piece of equipment in the facility will be cleaned and disinfected with industrial alcohol according to specific standards.

After learning about the sterile manufacturing environment, partners will explore the specific components of our production lines.

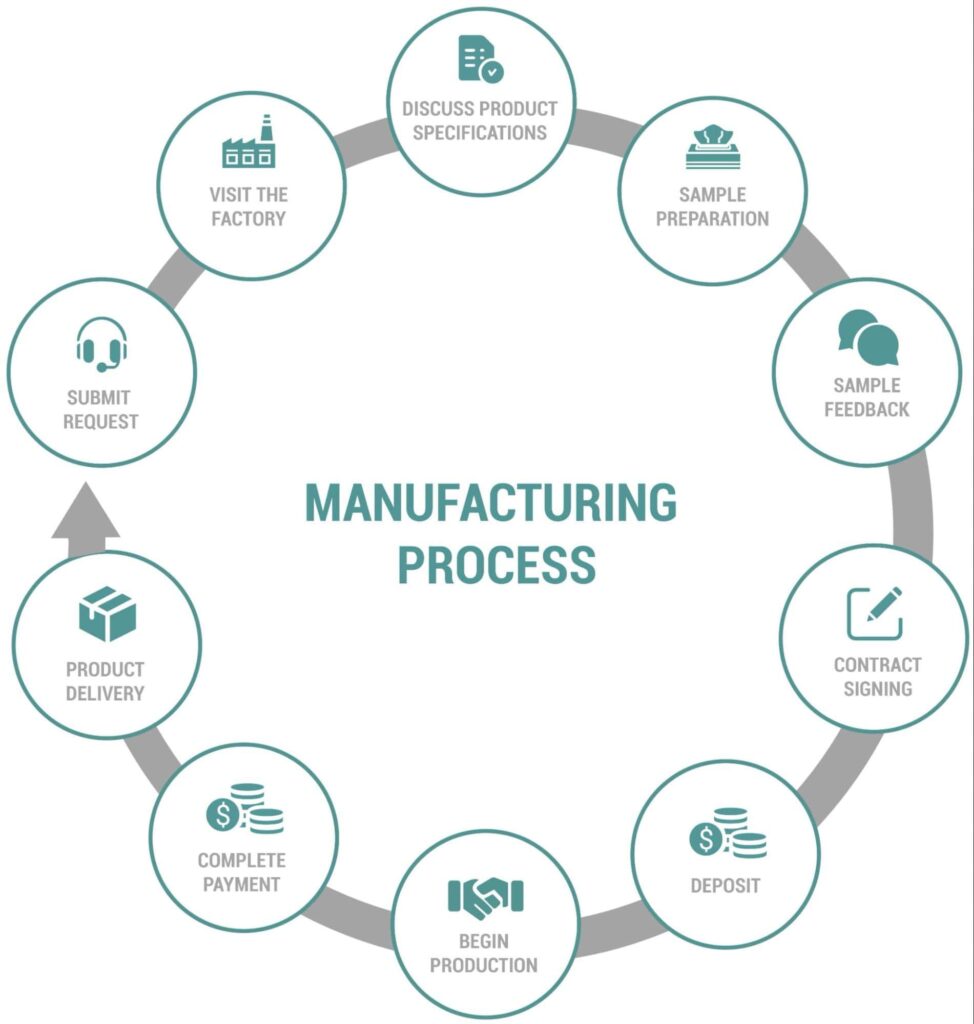

1- EDI water purification system

Electrodeionization (EDI), the most advanced water purification technique, uses electricity and ion exchange membranes to deionize water—separating dissolved ions (impurities) from water. Ultraviolet light is used to disinfect the water, resulting in a 99.9% pure product. Water with a pH between 4.5 and 5.5 is ideal for newborn skin, according to NICU – the American Foundation for Newborn Care. This pH supports the protection of the skin’s acidic cell membrane, prevents dehydration, and counteracts bacterial invasion.

2 – Visiting the wet wipes tissues production line of DHTI

To ensure that we can satisfy our partners’ diverse needs, we have invested in six manufacturing lines, as well as different printing systems and packaging equipment. These systems automate every manufacturing process, from fabric cutting and stacking through spraying, packing, capping, and stamping. Line managers check and evaluate the outcomes of each stage, including raw materials checking, chosen ingredients, and product weight. Our strict adherence to these standards assures that the finished goods are flawless and of the highest quality.

Partners will also have the chance to evaluate the fabric that will be used to manufacture the ODM wet wipes. Each of our fabric rolls meets the GMP (Good Manufacturing Practices) standard – a system that ensures products are manufactured and controlled according to quality standards, parameters, or information with clear certification documents. All information on production methods, raw materials, and ingredients at the DHTH factory is made public and accessible to all customers and partners.

After the automated line completes its task, workers perform quality checks on the product. They examine the package’s dimensions, balance the product volume, and resize the product as needed to meet sample specifications. If there are any deviations from sample requirements, we discard those items to make sure that every product given to the client is of the highest quality.

Step 3: Discuss product specifications – Conducting research

Following our tour of the production area, we will proceed to the lounge for a more in-depth discussion of the product’s attributes. Our team will discuss with partners some product-related aspects such as materials, active ingredients, scents, prices, packaging, production methods, etc., and will also provide partners with samples of our wet wipes to better visualize the product. We will assess partners’ feedback on these samples before moving on to sample research.

Step 4: Sample preparation

After finalizing the specifications, we will begin producing the sample and deliver it to your registered address.

Step 5: Partner responds on sample

After receiving the sample from DHTI, the partners will thoroughly inspect the product quality, including the wipe and packaging. If the sample product meets all requirements, we will proceed with production as previously registered. However, if the product is still in need of adjustment, we will continue to modify it until it meets our requirements.

Step 6: Contract signing

We, the manufacturer, and you, our partner, decide on the terms of the contract and sign it to safeguard each party’s respective interests during the partnership.

Step 7: Deposit

After signing the contract, the partner’s side is required to pay a 50% deposit on the total value of the order. The remaining 50% of the order price will be due after quality control and receipt of the product.

Step 8: Begin production

During this phase, DHTI will focus on ensuring production progress and quality. Our strict quality management process from start to finish will ensure output quality. Each shipment will have its own set of records detailing the whole manufacturing process, including the date and time of creation. This makes it simpler to monitor the progress and quality of an ongoing project.

Step 9: Overall payment

When DHTI has completed the entire order, the partner will inspect and pay the remaining 50% of the order total.

Step 10: Product delivery

Finally, DHTI will pack and prepare the packages for delivery to the partner. You can choose the appropriate delivery location (delivery at the warehouse, delivery at the point of sale,…). Currently, we are able to accommodate shipping methods depending on the needs and costs of the customer. When receiving the goods, you need to carefully check the quantity of the order. We will make compensation for damage to defective products in the following cases:

- Products do not meet the quality as originally committed (not accommodating standard basis).

- Damaged, unusable, or mistaken packaging design.

Find out more:

- Alcohol Wet Wipes Manufacturer: High-Quality, Trusted Products

- Wet wipe packaging manufacturer serving in the US

4. Why choose DHTI to make your own wet wipes?

With more than 23 years of experience in the wet wipe industry, DHTI – A reputable ODM/ OEM manufacturer has received the trust of various domestic and foreign partners who have placed orders for our ODM wet wipes.

4.1 A highly specialized R&D team creates outstanding products with superior features and high-quality

Ordering ODM services means you purchase a product that already exists in a manufacturer’s catalog. Because these products will be your own branded products, they represent your company image and quality. Therefore, finding the right ODM is crucial.

Two factors you need to consider when choosing an ODM manufacturer are outstanding features and quality products. A product with impressive content features will attract initial attention and encourage customers to find out more. Thereby, increasing the ability to boost sales and revenue. Moreover, a good quality product helps you gain profit in the long run because it increases customer satisfaction and loyalty.

First, we offer a wide range of products to meet the needs of all our clients, including baby wipes, cleaning wipes, antibacterial wipes and travel wipes. Our R&D team has over thirty years of experience in this field, which enables us to use only the finest materials in all our products. Therefore, our clients benefit from the resulting unique characteristics and superior performance.

For example:

- If your company wishes to market natural products, we prioritize using natural, benign ingredients.

- If your company wishes to produce baby wipes, we focus on producing wipes that are free of harsh chemicals and gentle to a baby’s delicate skin.

- If your company desires to sell products with superior functionality, we will focus on the most effective active ingredients.

Simply give us your antibacterial wet wipes manufacturer needs, and we will provide the optimal solution.

Understanding that quality is one of the great values a business wishes to offer its customers. We invest significant resources in our experts to conduct extensive research on the substances and ingredients used in wet wipes – especially their safety or scope of application. We do not use banned substances even though they are widely used and inexpensive, such as Paraben and MIT.

We take the production environment very seriously because it directly affects product quality. At the DHTI factory, the environment is aseptic—it does not contain any harmful microorganisms or fungi. During the production process, workers wear full protective gear and disinfect themselves before entering the factory. In addition, the line system is fully automatic and closed—human workers only manage product quality at each stage, limiting opportunities for bacteria to enter during production. DHTI is proud to be one of the owners of an OEM wet wipes facility with modern equipment systems and ISO 9001:2015-compliant quality management procedures. DHTI is proud to be part of an enterprise that has been recognized by the ISO as achieving exemplary quality management standards.

Our services will be especially beneficial to you when you are launching a product on the market. We can help you ensure that all legal documents and procedures are in place, so your business is well supported. Thanks to our high standards and experienced team, we have formed strong relationships with many of our ODM partners.

4.2 Optimizing production costs & time thanks to modern lines and large production scale

We own a large-scale factory up to 3000m2 which is equipped with 6 fully automated wet wipe production lines. This allows us to meet all of our partners’ production needs. With this fully automatic line, the machine will work almost all stages from cutting fabric to packing it without human involvement.

Our wet wipe manufacturing machines can produce 280 units per minute. In the 8-hour period, 112,000 units can be produced while the number of units in 12 hours is 156,700. As a result, large orders can be completed within short time periods so that customers are not left with insufficient stock.

Thanks to our factory’s large capacity and production scale, we can quickly respond to bulk orders. This allows you to provide high-quality goods at competitive prices.

4.3 We own several popular brands of wet wipes and have successfully exported products to the US market

We own different well-known brands of wet wipes, notably Mamamy baby wipes. Launched in 2007, Mamamy is currently one of the most popular brands among millions of Vietnamese consumers. Nielsen’s report indicates that Mamamy dominated the baby wipes market in 6 major cities (Ho Chi Minh City, Hanoi, Hai Phong, Da Nang, Nha Trang, Can Tho) from April 2016 to March 2018. Additionally, Mamamy’s products are available in more than 40 provinces and cities and 16000 retail outlets across Vietnam. This demonstrates that DHTI’s coverage of wet wipe products is extensive.

- Mamamy wet wipes gained the trust of many Vietnamese consumers

In addition, as proof of our constant product innovation, we have recently released Mamamy Tropical—an upgraded version of the original wet wipes. This is a “revolutionary” line of baby wipes made with 100% cloth natural fibers and rayon, safe for use by premature babies.

- Mamamy Tropical Tropical Wet wipes pioneers in the use of 100% natural fibers and rayon

See more: Wet facial tissues | Benefits & Tips to choose the right one for skin

In 2020, our Luck Lady alcohol wet tissue was one of the few lines of Vietnamese antibacterial alcohol wet wipes to be successfully exported to the United States. This success led to many follow-up orders, which remain strong to the present day. This achievement demonstrates our ability to produce competitive, high-quality products that can be trusted by consumers and sold on the international market.

- Luck Lady alcohol wipes line has been successfully exported to the US

4.4 Owning the trust of major domestic and foreign partners

Entering the wet wipes production market in 1999, DHTI has cooperated with many major partners, including:

- Mom and baby store chains: Kids Plaza, Bibomart, Baby, Tiniworld,…

- Retail chains: Bach Hoa Xanh, Liberico,…

- International Aesthetic Hospital: Dr. Hana.

Our mission is to serve our partners with the greatest standard of service, and our goal is to maximize their benefits. Therefore, we are proud to receive the trust and cooperation of businesses.

ODM wet wipes are a manufacturing option that can bring many benefits to businesses with limited resources and a lack of ideas for new wet wipes products. DHTI’s modern, professional manufacturing processes allow us to supply clients with superior wet wipes while also being cost-effective. As such, businesses can quickly launch their own wet wipe products into the market.

Related post

- Cosmetic wipes manufacturer: Best trusted products 2023

- Wet wipes supplier serving superior solutions worldwide