Wet wipes production is a growing industry with many businesses looking to capitalize on the increasing demand for these hygienic and convenient products. From selecting the right parts and equipment to securing materials, learn how to plan, set up, and run a successful wet wipes production facility.

Learn more: The leading & trusted wet tissue manufacturer in the market

1. How are wet wipes made?

Wet wipes are often manufactured from a mixture of nonwoven fabric, water and active ingredients for moisturizing, cleansing or disinfection. The production of wet wipes involves weaving the fibers into sheets, soaked them with water and addition substances (cleansing or moisturing ingredients).

To get ins and outs of wet wipes production process, continue reading the following section.

2. A complete wet wipes production process

A complete wet wipes manufacturing process involves several distinct steps and stages, starting from the selection of raw materials, environmental cleanliness, fabric cutting, packaging, to quality control measurements. Below, DHTI wet wipes manufacturer will have a detailed explaination of each step in the process:

2.1 Step 1: Prepare wet wipes materials

Each production shift has its own requirements and specifications, which are transmitted by the shift leader to technicians.

Next, the controller collects raw materials from the warehouse keeper and checks their quality. After checking all information must be recorded on a previously printed request sheet. This helps to track inventory accurately and easily saved; management or customers can check production batch information at any time.

When fabric meets quality and production requirements, it will be cleaned and put into production.

2.2. Step 2: Ensure the production environment

In the second step of wet wipes production line, we test and make sure the production environment is sterile (this is a condition that only factory or laboratory conditions can meet) – to ensure no harmful bacteria are present, which might affect product quality. We believe that a commitment to quality can only be guaranteed when every small step of the wet wipes production process is strictly inspected and controlled.

Before every production session, we start with disinfection, including disinfecting machines and all employees involved in the production process. Accordingly, each worker is wearing protective gear and disinfecting with industrial alcohol. Each type of machine will have its own characteristics and we have a separate standard evaluation table for each machine, the controller conducts tests according to each criterion and records the results. This helps our quality control to be strict, accurate and effective. Partners when working with us can also track the entire quality control process of each production batch through these records.

After checking the materials, the worker starts the machine and sets the product parameters:

- Fabric cutting size.

- Packaging size.

- Amount of water used to marinate the product.

- Determine the cut-off size.

- Set Production Date and Expiry Date.

With printers and packaging machines, workers perform the following steps: installing films, and decals (if any) on the shaft; then they install the machine.

- Set film and decal parameters based on the product’s requirements.

- Press the Confirm button to receive data that will determine the cut size.

- After packaging, check for product quality (if the package is damaged or there are any defects on the cap/sticker).

When checking and finding that the quality of the wet wipes production line is stable, adjust the machine to run in drift mode, the maximum speed does not exceed 285.

DHTI uses a fully automatic wet wipes production line, which means that once the machine is started, it will produce wet wipes without further human intervention. Workers monitor the production throughout to ensure there are no errors or need for timely corrections.

2.3. Step 3: Making active ingredient phase

After fabrics are folded by machine, they will be moved to the next stage: wetting. In this process, purified water (EDI water), antibacterial active ingredients, nutrients and moisturizing agents are added to or not depending on production requirements.

After the fabric has been checked, it will be sent to the cutting box.

2.4. Step 4: Cut the fabric

After cutting the fabric, it is folded and transferred to packing stage for further wet wipes production processing.

2.5. Step 5: Packaging & cap stickers

After the machine has completed its automated packing process, workers will check product quality and packaging. The finished products are then forwarded to the packing area with lidded shipments. DHTI offers a wide range of wipe substrates, formulations and containers.

2.6. Step 6: Check product quality and packing

In this step, the company will collect and test a few samples of each production batch. If there are problems with any of these batches, they will be recalled immediately. Employees check completed products to ensure that they are up to standard:

- Examine, remove and replace torn products.

- If the paper cut-out does not match the packaging size, re-calibrate.

- Check the weight of each package: If the package is underweight or overweight, it must be removed.

- Check the vapour content of the product.

DHTI will pack the approved batches of products according to the required quantity and specifications, then send them to the partner’s warehouse or point of sale.

| Conclusion:

Here is the answer to “How are wet wipes made?” – The “optimal” 6-step process for standard wet wipes production at DHTI that you can easily follow:

These are the steps of a fully automated wet wipes production line, but in the case of semi-automatic or mini lines, there may be more stages. |

If you need to order production, please contact DHTI to receive a free consultation on wet wipes production. We will be happy to provide you with more information about how we can help your business grow.

[maxbutton id=”1″ url=”https://dhti.vn/en/oem-philosophy/” text=”GET A QUOTE NOW” window=”new” nofollow=”true” ]

3. Choosing the right wet wipes production line

Owning a variety of machines is essential for producing wet wipes. Three types are commonly used: mini machines, semi-automatic production machines, and automatic machines.

For businesses that order wet wipes production, it is important to choose the right production line. Production scale, capacity, automation level (level of human involvement in the wet wipes production process), product success rate and cost are some of the factors to consider when making this decision. Below is a detailed analysis of three different types of machines:

| Mini machines | Automatic machines | Fully automatic machines | |

| Production scale | Small order, small quantity | Suitable for medium or large-scale production workshop. | Suitable for businesses that need to produce wet wipes in large quantities. |

| Capacity | 25 pcs/min | 30 – 120 pcs/min | 200 – 300 pcs/min |

| Automatic level Automatic | and requires 1 person to operate. | Some operations are manual, so it takes time and money to hire workers. | The wet wipes production process is fully automated by machines, saving labour (people only participate in the role of checking the quality of output products). |

| Output product success rate | Relative output product quality, many cases of low-quality products | High-quality products, few defective products. | Product quality is high, and uniform, very few defects. |

The above analysis has given the necessary information for you to select the appropriate wet wipes production line. If you are in need of becoming a wet wipes manufacturer, you are looking for a production line for wet wipes to meet a large demand for customers, or you are a wet wipes business and want to own a production line. For your own production, you should choose fully automatic or semi-automatic machines because these machines have high durability, and produce good quality products in the shortest time.

In case you do not have enough resources to invest in self-production but you still want to have wet wipes branded with your business, you should choose a factory with a modern and good production line of wet wipes and wet wipes. Especially owning a fully automatic line. The advantage of the 100% automatic line is that the machine’s capacity is large, thus helping to shorten the production time, which means that you will quickly get the desired amount of products in a certain time. In particular, this machine line always ensures good output product quality.

See more details in this post: Wet wipes manufacturing cost | Price of each machine

4. Why should you choose wet wipes manufacturing process at DHTI?

DHTI is antibacterial wet wipes manufacturer, private label wipes manufacturer certified with Quality Management System. Quality ISO 9001: 2015 – the latest version of ISO 9001, is one of the prestigious certifications that every manufacturer wants to have. Therefore, customers are always assured to order the production of wet wipes because the quality is always guaranteed.

4.1 Experienced R&D team to help offer maximum benefits for partners

DHTI has been manufacturing wet wipes for over 20 years, serving thousands of customers at domestic and abroad. When you submit a processing request, our team of experts will work with you to analyze and evaluate your specific requirements, including fabric material and active ingredients—tailoring the order to meet all of your specifications. We optimize resources so that you can achieve the best results possible for your brand and conveyable products that reflect the spirit of your business.

4.2 DHTI has the ability to create trend-leading products that help partners easily compete and stand out in the market

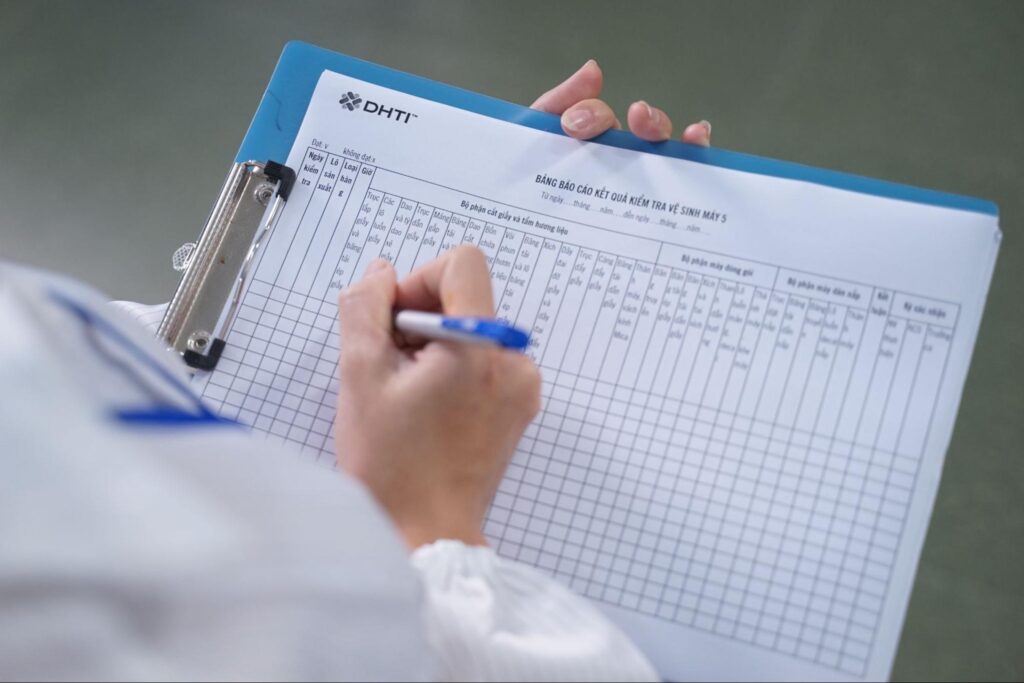

The spirit of “Best & Better” is the guideline throughout all activities of DHTI, we I constantly strive to create new products that are always better than the previous one. Not only are we a manufacturer, we also have our own brands of wet wipes that are already established in the market – such as the Mamamy baby wipes line.

Since its launch in 2007, Mamamy is the first line of unscented wet wipes in Vietnam and one of a few brands using antibacterial ingredients patented by the United States. Mamamy prevents diaper rash and heat rash in babies. In 2022, DHTI launched Mamamy Tropical – the first natural wet wipes brand in Vietnam. This product was developed using tropical natural ingredients (such as marigold essential oil, inca inchi essential oil…) to care for babies living in a tropical country.

If you have a desire to own the breakthrough wet wipes product lines, please share your ideas and wishes with us; we will work with you to achieve this goal.

4.3. Offer diverse packaging that can meet the needs of your customer base

Our creative design team works with businesses to create packaging that is memorable, impressive and true to their brand spirit. In addition, DHTI owns a state-of-the-art printing and production system that can accurately print colours and maintain high product durability.

4.4 Owning the trust of major domestic and foreign partners

Entering the wet wipes production market in 1999, DHTI has cooperated with many major partners, including:

- Mom and baby store chains: Kids plaza, Bibomart, Baby, Tiniworld,…

- Retail chains: Bach Hoa Xanh, Liberico,…

- International Aesthetic Hospital: Dr. Hana.

Our goal is to maximize our partners’ benefits, and we are proud of the trust clients have placed in us.

DHTI is also a manufacturer of wet wipes, and OEM wet wipes for international partners, especially in countries such as the US, and Taiwan,…

In addition to the trust gained from its production partners, DHTI is a reputable distributor of wet wipes throughout Vietnam with 16,000 retail points. Therefore when you order from DHTI, you can get quality products and designs that are sure to sell well at your store.

Especially, DHTI offers preferential programs for partners who order the production of wet wipes. If you are interested in owning high-quality wet wipes, please contact us for more information:

Address:

- Representative office: 69B Thuy Khue, Phuong Thuy Khue, Quan Tay Ho, Thanh pho Ha Noi

- Manufacturing plant: Lo CN7, Cum Cong Nghiep Tu Liem, Phuong Minh Khai, Quan Bac Tu Liem, Ha Noi.

- Hotline: 02437160270.

- Website: https://dhti.vn/en/

Understanding the wet wipes production process is vital to succeeding in this field. Hopefully, this article has brought you useful information, please follow other related articles on wet wipes production.

- OEM wet wipes method – All things wholesalers need to know

- ODM wet wipes | The leading wet wipes outsourcing company