Numerous factors impact the wet wipes manufacturing cost. What exactly is included in this cost? How much would it cost to buy all of the required wet wipes-making machines? Continue reading to discover the answers to the aforementioned questions.

Read more: White label wet wipes manufacturer – “Make your own wet wipes” solution

1. What is a wet wipe manufacturing machine? How many types of these?

Wet wipes manufacturing machine, as suggested by its name, is an industrial machinery that facilitates the creation of wet wipes from non-woven fabric. These machines perform a variety of activities, including fabric cutting, wetting, and product packaging.

There are now several types of wet wipes production machines on the market. In general, they are divided into two types: Semi-automatic Wet Wipes Machine and Fully Automatic Wet Wipes Machine. These machines are structurally identical, including the following components: Folding Machine, Slitter Rewinder, Wetting System, Lid applicator. The extent of human involvement is the most significant distinction between these two machines. With fully automatic machines – workers only need to participate in the final stage of product quality inspection, however, with semi-automatic machines, workers will be required to make adjustments at the end of each stage before moving on to the next.

Some other criteria compared below between the two models will help you understand the details of these two models:

| Semi-automatic Wet Wipes Machine | Fully Automatic Wet Wipes Machine | |

| Machine construction | A control system combined with an electromagnetic sensor. | Fully modern, cutting-edge automatic machines. |

| Types of wet wipes | wet clothes, personal hygiene products, baby wipes, wet facial tissues, and other items. | adult wipes, wet tissue alcohol, car cleaning wipes, baby wipes, flushable wet toilet papers, wet tissue, cleaning and household wipes, industrial wipes, and heavy-duty wipes. |

| Scale of production | Medium or large-scale production | Mass production |

| Capacity | 30 – 120 units/min | 280 units/min |

| Ability to change Product dimensions | – The ability to offer product lengths within a specific range.

– Can convert web widths 20″—80″ into almost any fold size and cut length. |

– Can produce wipes of varying widths and lengths.

– Offers a wide range of product dimensions and folding options, providing high levels of hygiene and safety. – Allows for easy change over between different products. |

| Human involvement | Manual packaging | Fully automated by machines, with no human involvement. |

| Final product success rate | – High quality.

– Less deviation. |

– High quality.

– Minimal deviation. |

| Average price range | $17,500 – $35,500 | $17,500 – $500,000 |

Conclusion:

Each type of machine has its own benefits and drawbacks. Therefore, if you wish to produce your own wet wipes, you should consider thoroughly your purposes and needs such as your desired scale of production (small or large); the budget that you are willing to invest,… After determining, you will have all the information you need to come up with a reasonable option. In case you want to produce wet wipes in large quantities, full-automated production lines are the most suitable. You can refer to the information about the average cost of the wet wipes machine presented below to make an informed decision.

| [maxbutton id=”1″ url=”https://dhti.vn/en/oem-wet-wipes/” text=”OEM WET WIPES” ] | [maxbutton id=”1″ url=”https://dhti.vn/en/odm-wet-wipes/” text=”ODM WET WIPES” ] |

2. How much do wet wipes making machines cost?

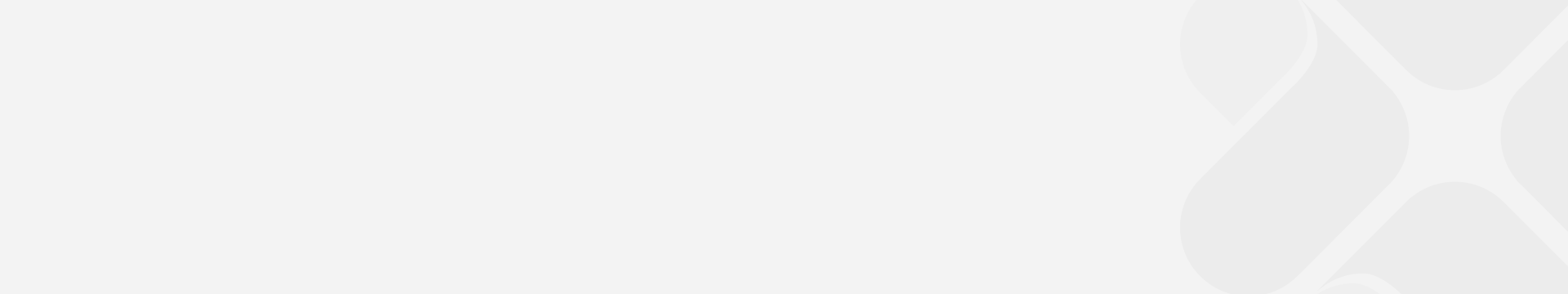

When evaluating the cost of a wet wipes machine, you should consider two factors:

- The initial cost of a wet wipes machine: the machine itself plus all the accessories.

- The lifetime (long-term) cost of owning and operating a wet wipes machine: The Total Cost of Ownership on a wet wipes machine includes everything you spend after the purchase including any replacements, repairs, operational costs and maintenance.

2.1 The initial cost of a wet wipes machine

The initial price of a wet wipes machine typically ranges from $17,500 to $500,000 (what many people refer to as the “wet wipes production cost”). However, the starting price may vary substantially from model to model. This cost is the same as the wet wipes making machine price mentioned in Part 1.

In fact, businesses often consider the up-front cost of purchasing a wet wipes production machine to be the total cost of this purchase, forgetting the long-term costs (implicit costs). Inaccurate or incomplete forecasting can lead to loss of control and cash flow, putting a business at risk of not being able to meet its operating costs. In many instances, companies underestimate the value of their products and publish them with low initial costs then raising prices later. Once this happens, it would be difficult for the company to regain customer trust and remain competitive for a long time. Find further information in the next section.

2.2 The lifetime cost of ownership associated with the wet wipes machine

The lifetime cost of wet tissue paper price production equipment has two main components: ownership and operating costs.

1. Ownership costs would include purchase cost, depreciation, insurance, taxes, erection, transportation, registration and investment costs.

2. Operating costs include labor (operator and maintenance), energy consumption, raw material, industrial space planning & maintenance, spare parts replacement, Repairs, Rejects, Change-over and any other consumable cost.

A large investment of capital will be needed if your business decides to purchase production machinery. Therefore, you should carefully consider each factor before making such an important decision.

Discover now: ODM wet wipes | Vietnam’s leading wet wipes outsourcing company

3. Investing in wet wipe making machines: Is it a good idea?

As mentioned above, a set of wet wipes manufacturing machines can be pricey. Furthermore, wet wipes manufacturing requires substantial expenditures in capital and labor. Specifically, if self-manufacturing is your preferred approach, you will need to invest in a variety of resources, including an experienced R&D team and a production team (staff and workers) to help you at every stage of the production process.

For a new business with no prior experience in the manufacturing process, it is critical to spend more time and money on research and development. If your products don’t meet specifications, you’ll need to modify them before putting them on the market—and that comes with certain risks.

Conclusion:

Investing in a wet wipes production machine is challenging, especially for businesses that urgently want a huge volume of high-quality products in a short time. The appropriate solution is to select a well-known manufacturer who can offer the goods in sufficient quantities and quality. You must ensure that they have a dedicated R&D team capable of generating products that convey the brand spirit and have high levels of competition.

DHTI is a leading antibacterial wet wipes manufacturer, offering an economical solution for branded wipes that require no high-cost machinery:

4. DHTI manufacturer – The solution to your own wet wipes brand

4.1 Our advanced and modern automatic machines help lower capital investment

Our manufacturing facility includes six cutting-edge production lines for all types of wet wipes, as well as printing and packing equipment to accommodate varying demands. This allows us to better fulfill your requirements and provide you with the highest wet wipe products at the lowest possible cost.

Our 100% automated production machines enable us to increase capacity, improve product quality and minimize errors. Our wet wipe manufacturing machines can currently produce 280 units per minute. In the 8-hour period, 112,000 units can be produced while the number of units in 12 hours is 156,700. As a result, large orders can be completed within short time periods so that customers are not left with insufficient stock.

4.2 Our R&D experts offer innovative solutions to optimize your profits

Our R&D team is highly specialized in the industry, clearly understanding the ingredients and their application in wet wipes. This means that we can produce products tailored to your specifications. We work with many reputable suppliers, which allows us to help you optimize the cost of production materials.

Our professionals regularly research recent trends in ingredients to design superior formulas. We also update the legality of the materials we use, their scope of application and allowed usage rates. For example, some common preservatives such as parabens and MIT (methylisothiazolinone) are no longer used in our wipes due to their negative effects on human health.

Learn more: Private label wet wipes manufacturer – “Make your own wet wipes” solution

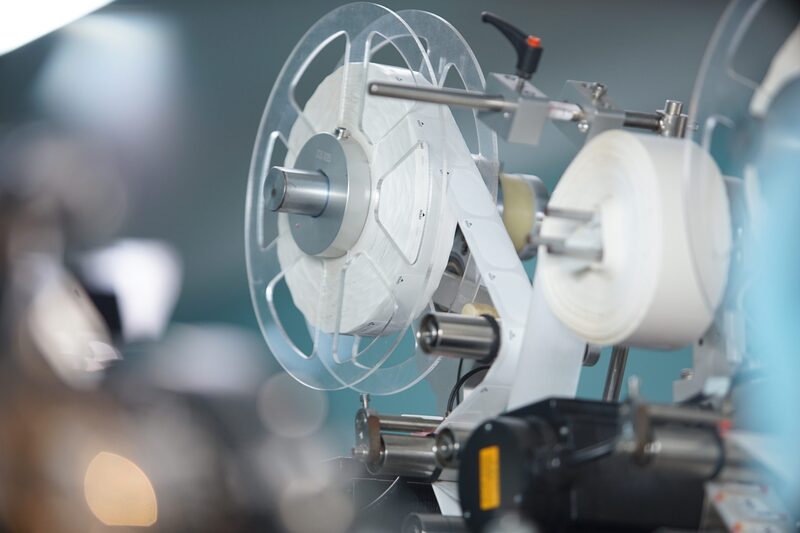

4.3 Our product quality assurance due to ISO 9001:2015 certification quality management system

We have developed and implemented a strict quality-control process in the production of wet wipes from start to finish. Our supervisors check and measure the products regularly to ensure that each stage of production operates under sterile conditions. This minimizes errors in the final product before it reaches customers.

Workers are regulated to wear protective gear when entering the factory. At the beginning and end of every shift, production areas will be disinfected with industrial alcohol. Machines are periodically checked, cleaned and disinfected. The supervisor will then conduct tests and record cleaning results of each machine.

Once the products are completed by the automatic line, our staff conduct quality control checks. To ensure the quality of each product, we take a number of samples from each production run to be re-tested in the laboratory. Only when products pass inspection, the packaging is implemented. Then, our staff will check the shape of the product packages, reweigh and measure each product to ensure the packaging meets specifications. Any products that fail inspection are sent back without being shipped to our partners.

4.4 Owning the alcohol wet wipes imported in the USA market

We manufacture a variety of wet wipes: baby wet wipes, cosmetic wet wipes, antibacterial wet wipes…to meet different needs. In 2020, Luck Lady Alcohol Wipes passed the rigorous standards of the U.S. market and was successfully exported to this country. The number of orders for wet wipes has rapidly increased and maintained good sales since then. This demonstrates that DHTI has the ability to create products that are not only highly competitive but also meet international standards.

4.5. We offer a variety of shipping methods to meet our clients’ needs

Understanding the commercial terms especially Incoterms will help our company ensure a smooth and speedy delivery to our partners. Without an understanding of the law, however, delivery through different countries could cause trouble, as well as longer delivery times. The product may even be recalled for inspection.

DHTI has all relevant documents and procedures available for each form of transportation, which helps customers feel secure in choosing the most suitable shipping option for their needs. Our client needs to share information, customer service representatives will advise on the best method of shipping.

For our international customers, we offer a number of transportation modes:

- EXW (Ex Works).

- FOB (Free on Board).

- Door to door.

- CIF (Cost, Insurance and Freight).

DHTI offers all of the choices above, we will tailor our options to meet your needs and help you find one that best fits your budget.

In conclusion, the wet wipes manufacturing cost depends on many different factors. If your business has a tendency to join this industry, you have to consider thoroughly before decision because the wet wipes making machine price is super high. Therefore, it is suggested that you should choose a professional manufacturer to do it for you. Please contact DHTI via this address for more support:

Dong Hiep Trading and Investment Joint Stock Company

- Website: https://dhti.vn/en/

- Hotline: (84-24).3716.0270.