Spunlace non woven fabric for wet wipes is a very popular material and has gained popularity due to its excellent properties. So, what is spunlace non woven fabric? What are they commonly used in the wet wipes industry? How can they be made of? Let’s learn more about this material in wet wipes production in this article.

See more: Private label wipes manufacturer – “Make your own wet wipes” solution

1. What is spunlace non woven fabric?

Spunlace non woven fabric for wet wipes are a nonwoven manufacturing systems that uses high-pressure water flow to tangle the fibers. Under the water power, the fibers would move and rearrange and bond together. Thereby, these fiber web is strengthened to provide qualified physical and mechanical properties. In other words, spunlace nowoven is a composite of different fibers, through the production process, they will be closely linked together in the web to form a durable non-woven fabric for wet wipes production.

2. Spunlace non woven fabric manufacturing process

The manufacturing process of spunlace non woven fabric for wet wipes involves several stages.

Fiber preparation:

Firstly, fibers are fed, weighed, and fine-opened through a blending box and a fine-opening machine. When choosing fibers for spunlace nonwoven fabrics, factors such as cost, machinability, and the finished product’s intended use are considered. Both natural and chemical fibers can be used in the manufacturing process.

Mixed carding and fiber web formation:

The next stage is mixed carding, which evenly distributes the fibers and forms a single fiber. This fiber is then blended and has impurities removed to form a fiber net.

The purpose of fiber web formation is to create a loose structure from the fiber material. This can be achieved through various methods, including dry laid, wet laid, or polymer extrusion web formation.

Stretching and water jet strengthening:

Strengthening the fiber web is carried out using a process involving stretching and a water jet to enhance its mechanical properties and appearance.

Functional Finish:

Finally, a functional finish is applied through mechanical and chemical methods to improve the nonwoven fabric’s performance, function, and appearance. Coating and laminating processes can also be used for spunlace nonwoven fabrics to improve their serviceability and lifespan.

Learn more about the OEM và ODM wet wipes:

- ODM wet wipes | Vietnam’s leading wet wipes outsourcing company

- OEM wet wipes method – All things wholesalers need to know

3. Why spunlace non woven fabric is the best common used material in wet wipes production?

Spunlace nonwoven fabric is the best commonly used material in wet wipes production due to its unique characteristics. The manufacturing process uses water power to bond the fiber web, producing excellent physical and mechanical properties well-suited for wipe production needs. This fabric is eco-friendly because it does not require a chemical binder.

The even distribution of fibers within the web provides excellent longitudinal and transverse tension, making it less likely to tear during usage. Additionally, the fabric does not shed fibers during use, making it ideal for cleaning. The material feels soft and will not scratch the surface being cleaned. It also has a super-strong absorbing capacity and good ventilation.

4. Fibers used to make spunlace non woven fabric for wet wipe production

To cater to the requirements of various types of wet wipes, it is essential to offer diverse material compositions specific to the kind of specific wipe type.

4.1 Cosmetic/Baby wipes composition options

Some commonly used ingredients in cosmetic wipes/ baby wipes are viscose+PET, woodpulp+cellulose and pure cotton.

Viscose+PET (polyester)

Viscose and PET can be combined in different ratios, such as 3:7, 5:5, or 7:3. The higher the ratio of viscose, the higher the production cost. However, wipes with a higher viscose content are softer and have a higher absorbing capacity. The 5:5 ratio is a cost-effective option.

Woodpulp+cellulose

Woodpulp fibers are known for their excellent cleaning and absorbing properties, while cellulose fiber is derived from plants. This composition option offers biodegradable benefits for baby wipes and can reduce production costs.

Pure cotton

For high-end cosmetic/baby wipes, 100% cotton material is the best option. Cotton fibers provide high tensile strength, super soft skin touch, and high absorbing capacity, resulting in a great user experience. However, the price of pure cotton wipes is much higher than other composition options.

4.2 Flushable/Biodegrable wipes composition

Flushable/biodegradable wet wipes are popular due to their eco-friendly benefits. The most common composition option for flushable wipes is a combination of wood pulp and viscose, with varying ratios to ensure they can be safely flushed down the drain.

For biodegradable wet wipes, options include bamboo, cotton, and wood pulp. It’s important to avoid using PET or PP fibers as they are not biodegradable.

Discover now: Nonwoven fabric in wet wipes | Types, Features & How to choose

5. Pattern types of spunlace nonwoven

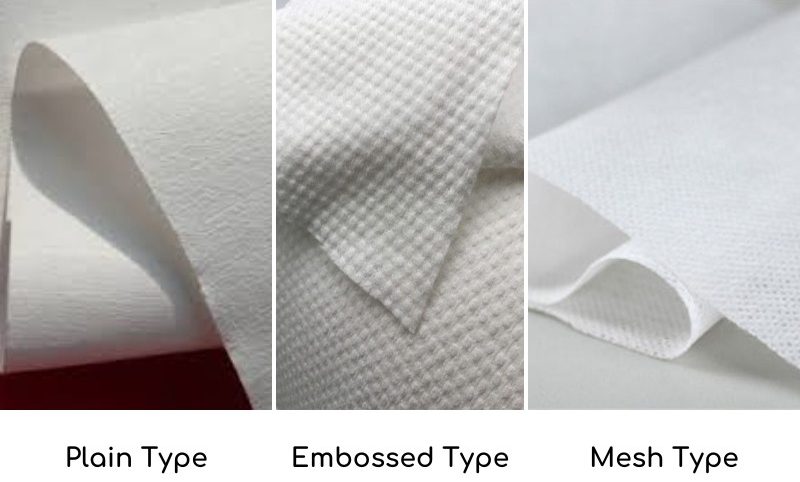

There are three patterns for spunlace non woven fabric for wet wipes production: Plain (parallel lapping), Embossed, and Mesh (cross lapping). Each pattern has a different appearance and cost.

The Plain type is the cheapest, while the Mesh type is the most expensive. Although the Plain pattern has less tensile strength than the Mesh type, it is strong enough for general-purpose wipes used for body cleaning. On the other hand, for wiping cloths, the cross-lapping pattern of spunlace nonwoven fabric is better since it is not easy to tear.

6. Thickness options of spunlace non woven fabric for wet wipes material

Nonwoven fabrics’ thickness is measured in g/m2, indicating the weight per square meter. For example, 50gsm means the material weighs 50 grams per square meter. Thicker material is generally better than thinner material but comes at a higher cost. For wet wipes made with spunlace nonwoven fabrics, 40-60gsm is ideal for daily use. Higher than this range is not recommended because it increases the cost, but consumers may not notice much difference in thickness.

7. Requirements for spunlace non woven fabric

Certain prerequisites must be met in order to produce spunlace non woven fabric for wet wipes.

- The manufacturer ought to create bespoke material specifications and technical parameters that cater to the diverse applications of wet wipes. The use of eco-friendly fiber materials should be prioritized.

- All raw materials used should comply with the requirements for baby products.

- The workshop must control environmental conditions, including temperature, moisture, and cleanliness.

- To ensure product quality, several pieces of equipment should be equipped during production, including online inspection of surface defects, online digital weight measurement, online monitoring of moisture content, metal detectors, and auto-tensiometers for material cutting.

- The manufacturer should use computer-controlled automatic production lines and fully automatic high-efficiency water circulation systems during production. Clean energy should be used for the overall production process.

- The manufacturer should have a microbiology laboratory, automatic electronic strength tester, bake oven, electronic balance, thickness gauge, buckling length tester, pH tester, and standard light box, among other equipment.

8. Quality inspection process of spunlace non woven fabric for wet wipes production

8.1 Quality inspection checklist

Quality inspection checklist for spunlace non woven fabric for wet wipes production:

- Packaging: Jumbo roll should be packed tightly, sealed, and complete, free from moisture, damage, and other pollution. There should be no dirt, insects, or foreign matter.

- Surface quality: The fabric should have no cracks more than 4/m2 and should be flat with no apparent wrinkles and fluff. The cutting edge should be smooth and soft, with no hair.

- Color and thickness: The color should be evenly distributed, and there should be no difference between the inner and outer layers. The thickness difference between the thickest and thinnest parts on the same surface should be less than 6% of the nominal thickness.

- Inner paper core: The fabric should be flat with an inner paper core, with no fluff or deformations. Tolerance under 3mm is allowed.

- Joints: Only one joint is allowed for each roll, with a prominent label for the joint (red mark).

- Width of rolls: The width of the rolls should be within the specified range: 180mm±2mm, 200mm±2mm, 210mm±2mm, 360mm±3mm (or based on contract requirements).

- Basis weight: The basis weight should be within the specified range: 40g/m2±5.0%, 50g/m2±6.0%, 55g/m2±6.0%, 60g/m2±6.0% (or based on customization requirements).

- Holes: No hole should be more significant than 3mm, and the number of holes less than 3mm should never be more than one per 200m2.

- Breaking strength: The breaking strength should be within the specified range, depending on the direction and the type of lapping.

- Breaking elongation: The breaking elongation should be within the specified range, depending on the direction and the type of lapping.

- Microbial contamination: The total number of microbe colonies should be ≤200cfu/g, and the entire fungal colonies should be ≤20cfu/g.

- Fiber diameter: The average diameter should be ≤10dmm and the maximum diameter should be <15dmm (or based on contract requirements).

8.2 Quality inspection rule

To ensure quality, inspections should be conducted on batches from the same supplier. If any of the items, such as breaking strength, hygienic index, absorption capacity, or thickness, are found to be unqualified in a batch of spunlace nonwoven fabrics, the entire batch will be considered unqualified.

In conclusion, spunlace non woven fabric for wet wipes is a crucial material. The unique manufacturing process and superior performance made it the preferred choice for wet wipes production. As the demand for wet wipes continues to rise globally, spunlace non-woven fabric’s versatility and performance will undoubtedly play a significant role in meeting the market’s needs.

Dong Hiep Trading and Investment Joint Stock Company:

- Representative office: 69B Thuy Khue, Thuy Khue Ward, Tay Ho District, Ha Noi City.

- Manufacturing site: Lot CN7, Tu Liem Industrial Cluster, Minh Khai Ward, Bac Tu Liem District, Ha Noi City.

- Hotline: (84-24) 3716 0270.

- Website: https://dhti.vn/

Related posts: