Are you searching for methods of making wet wipes, or would you like to get to know OEM wet wipes? What kind of production method is this? What should you consider when choosing an OEM for your product? The article below will give you the answers, helping you make the finest business decision possible.

Learn more: DHTI – Private label wet wipes manufacturer | “Make your own wet wipes” solution

1. OEM wet wipes manufacturing service for your brand

Wet wipes have become an important part of our daily life, with a wide range of products catering to each need such as baby wipes, face wipes, hand wipes, etc. The increased demand for wet wipes has created more opportunities for retailers, wholesalers,… to bring their products to life.

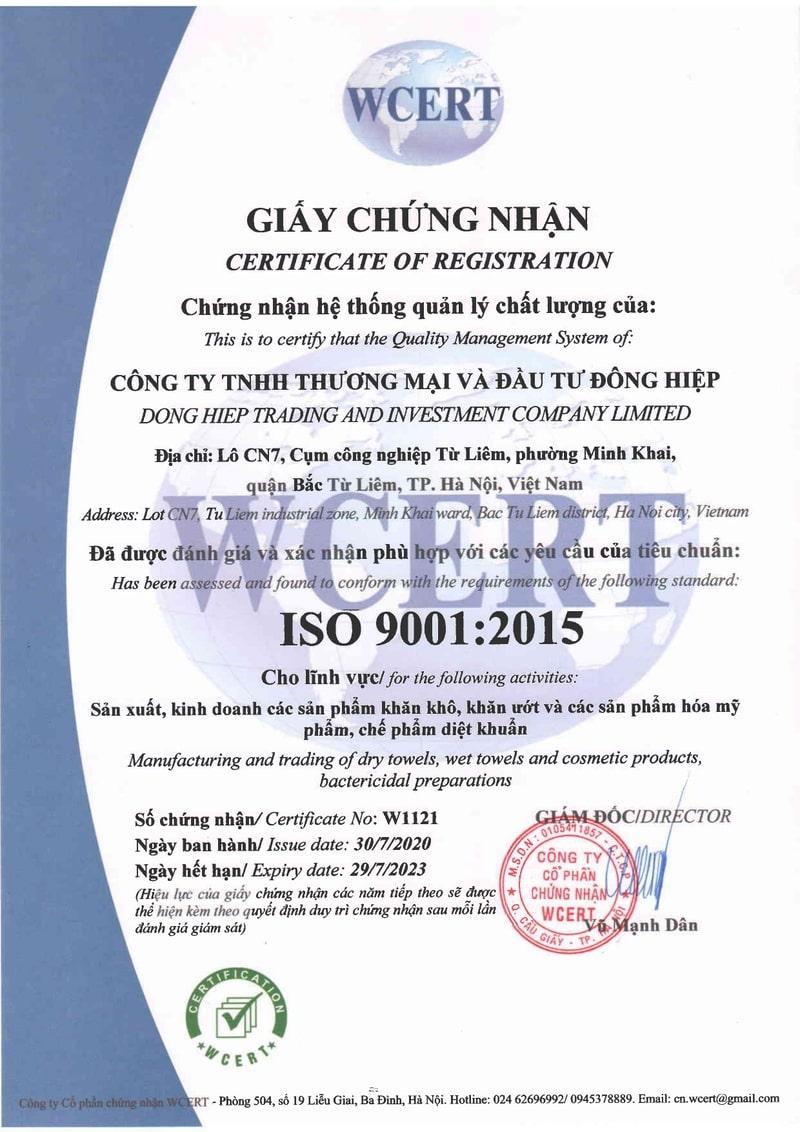

If you wish to have your own wet wipes brand, don’t hesitate to contact DHTI – the leading OEM wet wipes manufacturer. Made from customized formulations through an ISO-certificated process, wet wipes produced by DHTI can keep their soft, absorbent and gentle properties, while still delivering the users with a safe, skin-friendly touch. We always research and select natural ingredients to create high-quality products at the cost-effective and reasonable price.

See now: ODM wet wipes | Vietnam’s leading wet wipes outsourcing company

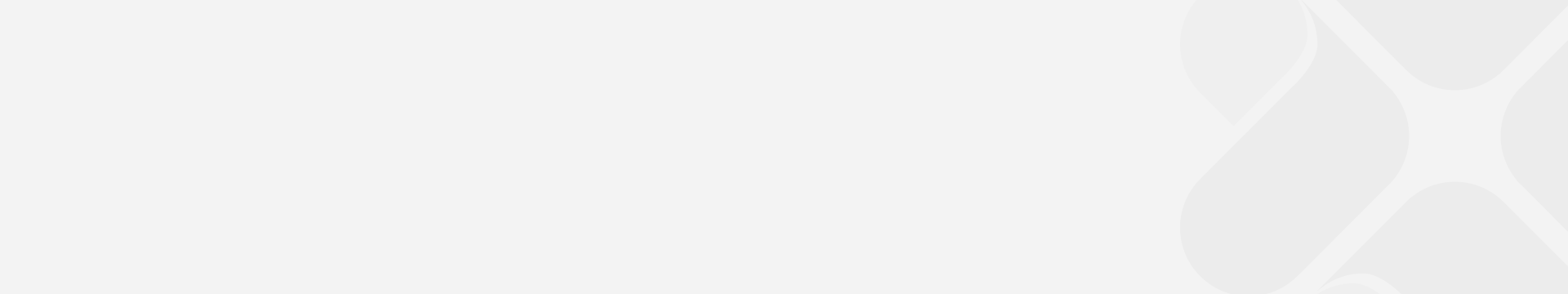

2. OEM wet wipes manufacturing process at DHTI

As a professional and experience OEM wet wipes manufacturer, DHTI owns advanced and cutting-edge production lines for various high-quality products. Our company’s OEM wet wipes manufacturing process consists of the following steps:

Step 1. Submit request – Consultants:

Upon receiving your order, we will proactively contact you to determine your product expectations (such as the product type, product users, product design,…). After gathering enough information and understanding your needs, our team of experts will conduct research to determine the optimal production solution.

Step 2. Direct visit to the factory:

You will be invited to visit our wet wipes factory in Hanoi (specific address: Lot CN7, Tu Liem Industrial Cluster, Minh Khai Ward, Bac Tu Liem District, Hanoi). Before approaching the manufacturing area, we will provide partners with sanitized protective clothing.This is required to ensure that the production environment is hygienic and free of hazardous pollutants, fungus, and microorganisms..

Step 3. Discuss product specifications – Conducting research

After completing the visit to the production area, we will proceed to the lounge for a more in-depth discussion of the product’s attributes. To be more specific, our team will discuss with partners some product-related aspects such as materials, active ingredients, scents, prices, packaging, production methods, etc. Partners will also get a sample of our wet wipes to better visualize the product. Following agreement on the manufacturing specifications, DHTI team will perform sample product research.

Step 4. Sample preparation

After finalizing the specifications, the production team will begin producing the sample and deliver it to your registered address.

Step 5: Partner responds on sample

After receiving the sample from DHTI, partners should thoroughly inspect the product quality, including the wipe and packaging. If the sample product fits the parameters agreed upon by both sides, we will proceed the production as previously registered. However, if the product is still in need of improvement, we will continue to adjust the sample product until it meets the requirements.

Step 6: Contract signing

We, the manufacturer, and you, our partner, decide on the terms of the contract and sign it to safeguard each party’s respective interests during the partnership.

Step 7. Deposit

A 50% deposit of the entire order value is due at contract signing, with the remaining balance due upon completion of production and the partner’s inspection of quality.

Step 8. Begin production

During this phase, DHTI will concentrate our efforts on ensuring production progress and quality and begin production. As stated earlier, our strict quality management process from start to finish will ensure output quality. Each shipment will have its own set of records detailing the whole manufacturing process, including the date and time of creation. This makes it simpler to monitor the progress and quality of an ongoing project.

Step 9. Complete payment

When DHTI has completed the entire order, the partner will check the quality and pay the remaining 50% of the order total.

Step 10. Product delivery

Finally, DHTI will pack and prepare the packages for delivery to the partner. You can choose the right delivery location. Currently, we can accommodate different modes of transportation depending on the needs and costs of our partners. When you pick up your order, it is crucial to double-check it. We will compensate for damage to the defective product in the following cases:

- The products do not satisfy the initial quality commitment (not reaching the product quality standards).

- The package is damaged, useless, or of incorrect design.

Read more:

- Wet wipes manufacturing cost | Price of each machine [Updated]

- Wet wipe packaging manufacturer serving in the US

3. Why should you choose DHTI as your OEM wet wipes manufacturer?

As a professional wet wipes manufacturer with over 23 years of experience, DHTI can provide numerous types of wet wipes with diverse specifications and uses. Our OEM wet wipes products are made through the strict quality control system to ensure the best wet wipes with these advantages:

- Non-irritated and skin-friendly: Our wipes are made up from the natural and gentle ingredients with no paraben, no dyes,… , therefore being safe for even delicate skin like the baby skin.

- Customized for each need: With the comprehensive OEM wet wipes manufacturing services, we can offer customized products from formulas, colors, sizes, ingredients, packaging,…

- Reasonable price: Thank to the advanced technology and cutting-edge wet wipes production lines, we’ve helped a lot of retailers and wholesalers to deliver their own wet wipes brand to the market at the competitive prices.

3.1. DHTI offers R&D support to provide partners with the most profitable solutions possible

With more than 23 years of expertise in wet wipes manufacturing, we have implemented numerous large and small projects both domestically and internationally. Therefore, we can utilize our experience to guide your business toward the most profitable manufacturing solutions.

Our team of industry experts is well-versed in the composition and uses of each wet wipes component, despite the huge number of available raw materials. As a result, we can fulfill all of your company’s product specifications. Moreover, we also collaborate with several long-standing raw material suppliers, therefore optimizing the cost of materials.

Our seasoned and highly skilled R&D team always strives to remain ahead of the competition when it comes to sourcing raw materials for wet wipes. We continually update the most recent information regarding the legality of each material’s subject matter, its area of application, and recommended dosage. Moreover, to safeguard the health of consumers, our products do not include any globally prohibited substances. Consequently, we are able to produce innovative wet wipes products that not only meet the industry standard but also set the manufacturing trend.

For instance, instead of using forbidden preservatives such as MIT or Parabens, we use Benzalkonium Chloride, which is FDA-approved for the safe storage of wet wipes. Antimicrobial active ingredients like Chlorhexidine Gluconate, which the World Health Organization (WHO) recommends for gingivitis, and Coco phosphatidyl PG-dimonium Chloride, a US-patented ingredient, are included in our baby wet wipes to aid in the treatment of common baby ailments such as diaper rash and skin infection. This allows us to not only fulfill the demands of the company but also conform to national and international standards.

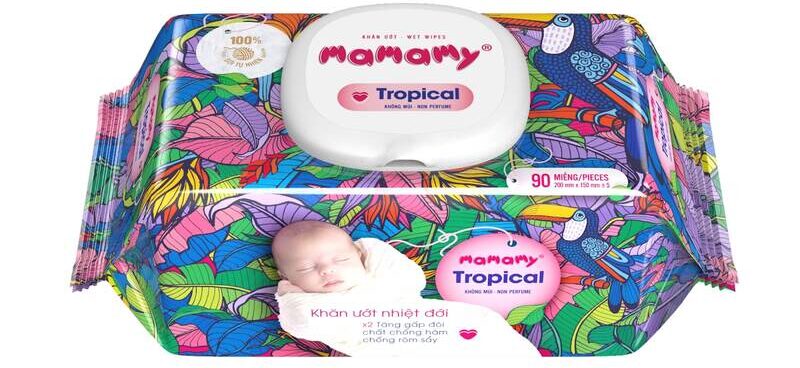

Through our partnership, you will be able to provide customers with highly practical wet wipes products. This assertion is reinforced by the fact that we have been a distributor of wet wipes for over 23 years, serving millions of local and international consumers, and owning well-known wet wipes brands such as Mamamy. Therefore, we are also able to understand the needs of your business customers. Partners that work with DHTI and place OEM wet wipes orders will receive finished goods of excellent quality and practicality, satisfying the demands of the market and the company’s clients without costing a fortune.

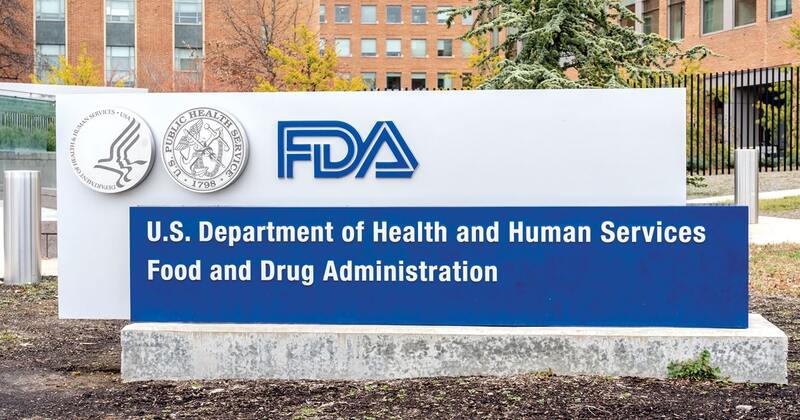

3.2. ISO 9001: 2015-compliant quality management procedures ensure product quality

DHTI is proud to be one of the owners of an OEM wet wipes facility with modern equipment systems and ISO 9001:2015-compliant quality management procedures.

From the preparation of raw materials to the production of finished products, we have established a strict quality process. We also possess a sterile, closed production environment with fully automated wet wipe production lines, from fabric cutting to impregnation to packing and product completion. At each stage, our staff will do a thorough inspection of the operation such as determining if the fabrics are cut according to requirements, whether the product’s weight meets specifications, whether the packaging is accurate,…

Our workers are provided with protective clothing, disinfected, and inspected thoroughly before entering the factory. Machinery and equipment are cleaned regularly with alcohol to avoid bacterial contamination affecting the product quality. This is one of the reasons why overseas consumers are satisfied with DHTI and prefer collaborating with us.

3.3. We own several popular brands of wet wipes and have successfully exported products to the US market

We own different well-known brands of wet wipes, notably Mamamy baby wipes. First appearing in 2007, Mamamy is currently one most popular brands among millions of Vietnamese consumers. According to Nielsen’s report, Mamamy dominated the baby wipes in 6 major cities (Ho Chi Minh City, Hanoi, Hai Phong, Da Nang, Nha Trang, Can Tho) from April 2016 to March 2018. Additionally, Mamamy’s products are available in more than 40 provinces and cities and 16000 retail outlets across Vietnam. This demonstrates that the coverage of the wet wipes products produced by DHTI is extensive.

In addition, as proof that we are constantly at the forefront of product invention, we have recently launched an upgraded version of Mamamy wet wipes – Mamamy Tropical. This is a “revolutionary” line of wipes in the use of wet cloths with 100% natural fibers and rayon, safe for use with premature babies.

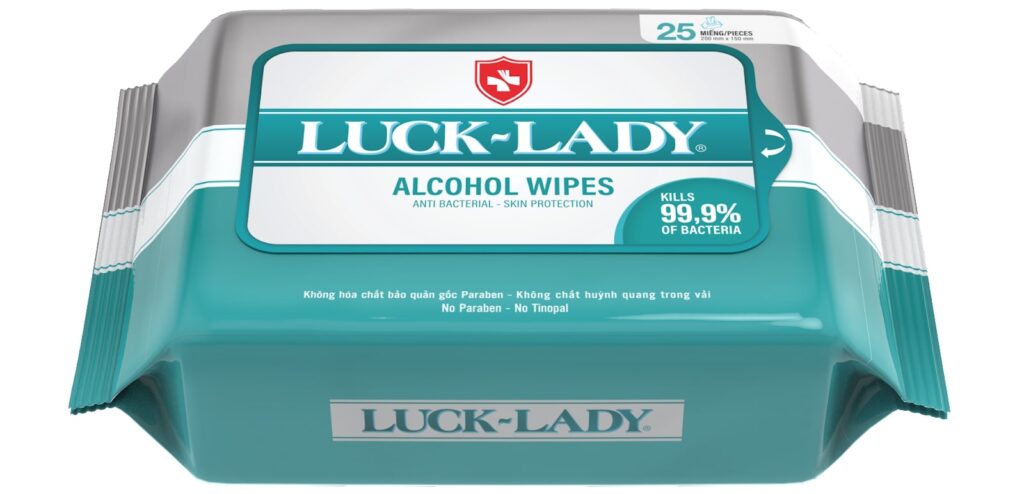

In 2020, Luck Lady alcohol wet tissues of DHTI was one of the few lines of Vietnamese antibacterial alcohol wet wipes to be successfully exported to the United States. After the preceding milestone, the number of orders still increased strongly and has remained robust to the present day. This proves that we are able to produce products that are not only very competitive and quickly gain consumer trust, but are also of exceptional quality and can be sold on international markets.

Discover more: Alcohol wet tissue – Best-rated antibacterial wipe 2023

If you’re searching for a reliable, highly specialized OEM wet wipes company that can provide your company with high quality, distinctive and competitive goods, we are certain that we can exceed your expectations.

Learn more:

- Quality and Affordable Antibacterial Wet Wipes Manufacturer 2023

- Alcohol Wet Wipes Manufacturer: High-Quality, Trusted Products

3.4. Owning the trust of major domestic and foreign partners

Entering the market of wet towels production in 1999, DHTI has cooperated with many major partners, including:

- Mom and baby store chains: Kids plaza, Bibomart, Baby, Tiniworld,…

- Retail chain: Bach Hoa Xanh, Liberico,…

- International Aesthetic Hospital: Dr. Hana.

Our mission is to provide our partners with the highest quality of research and service… Therefore, we are proud to receive the trust and cooperation of businesses.

4. OEM product lines/ OEM wet wipes products at DHTI

Currently, DHTI’s OEM process applies to various types of wet wipes; you may select the one that best meets your business’s requirements:

- OEM baby wipes.

- OEM personal care wet wipes.

- OEM antibacterial and disinfectant wet wipes.

- OEM restaurant and hotel wipes

- OEM airlines wet wipes.

If you have any needs for wet wipe manufacturing, we fulfill them and exceed your expectations.

Dong Hiep Trading and Investment Joint Stock Company:

- Representative office: 69B Thuy Khue, Thuy Khue Ward, Tay Ho District, Hanoi City

- Factory address: Lot CN7, Tu Liem Industrial Cluster, Minh Khai Ward, Bac Tu Liem District, Hanoi

- Hotline: (84-24).3716.0270.

- Website: https://dhti.vn/en/

OEM wet wipes is an excellent manufacturing option that brings many benefits to businesses. With a modern, professional manufacturing process, DHTI is capable of creating superior wet wipes that exceed high-quality criteria while being cost-optimal. Accordingly, your branded wet wipes will have more chances of reaching more consumers and provide you with a competitive advantage in the market.

Other relevant information about OEM wet wipes and ODM wet wipes:

- Wet Wipes Supplier Serving Superior Solutions Worldwide

- Leading & Experienced Disinfectant Wipes Manufacturer DHTI