About DHTI

Factory and Certifications

DHTI Factory overview

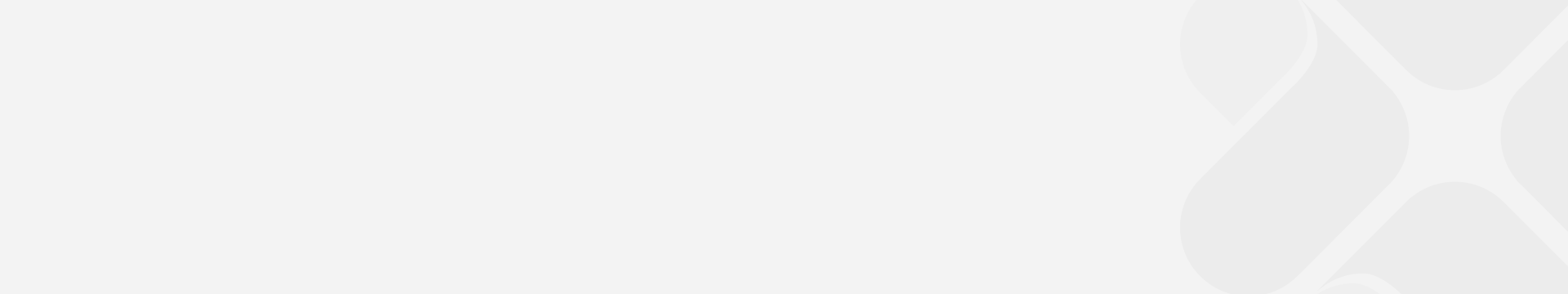

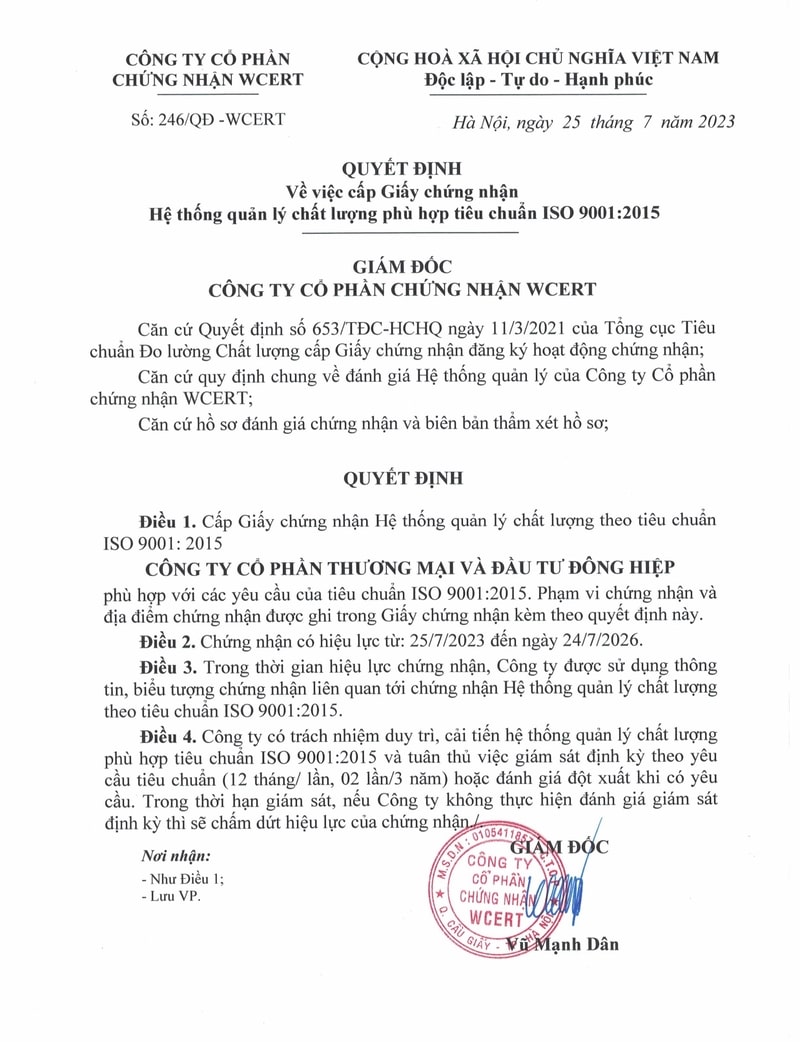

Established in 1999, we have more than 23 years of expertise in the wet wipes production sector. Our plant is equipped with cutting-edge technology and machinery, and robust quality control systems in accordance with ISO 9001: 2015. Moreover, the training programs for staff are executed methodically and periodically to reinforce their production skills and capabilities.

According to research published by the global measurement organization AC Nielsen in 03/2017, DHTI ranks first among the top five wet wipes producers in Vietnam (market share across the industry according to the March 2017 data period in 6 major cities).

Production environment

Providing a high-quality product is our first priority, therefore we pay careful attention to the manufacturing environment, machinery, and equipment, as well as all other variables that contribute to product quality.

About DHTI’s factory:

The factory of DHTI has a total area of 3000m2 and three floors

Air conditioning systems in production areas

Water filtration systems

99.9% EDI pure water

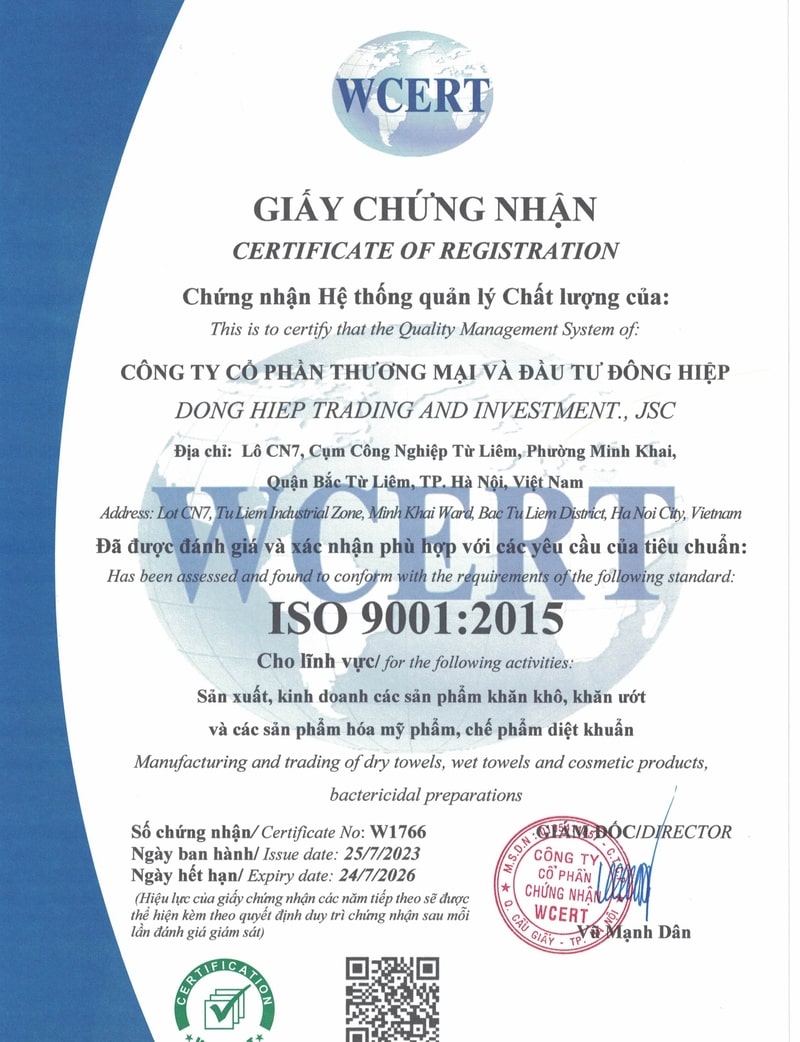

Certifications

Machinery and equipment

To diversify, and standardize all products and make it easier for you to broaden product diversity, we have invested in:

- Six automated production lines for wet wipes of all kinds

- System for the manufacturing of shampoos, face cleansers, detergents, etc., with various specifications.

Our production lines are routinely maintained, and components are periodically updated, resulting in consistently qualified and high-quality goods. We continually invest in cutting-edge assembly lines to keep up with the market’s fast expansion.

Quality management process

Product quality management from supplier selection to product delivery is the most crucial part in determining the quality of finished goods. This is usually a challenging procedure that requires preciseness, meticulousness, consistency, and tight control.

With the responsibility of ensuring the quality of your goods as an integral part of your business, we have developed the most complete quality control standards and methods, including:

– Provide training to individuals who are directly involved in the production of products so they can understand the regulations and standards and implement the quality control method to every product.

– Quality control team training including KCS and testing specialists. This team will monitor quality at every stage in order to ensure that it is carefully controlled and hazards are kept to a minimum.

– Employ an active laboratory to periodically test the microbiological qualities of the products and to evaluate new formulas prior to mass manufacturing.

– Cooperate with reputable domestic and international testing laboratories in order to regularly verify compliance with appropriate quality norms.

– Research and implement the most up-to-date quality standards in the globe

We are certain that you will be pleased with the product’s assured quality. Please feel confident in entrusting us with your brand.

Tiếng Việt

Tiếng Việt