The process of cold wipes production and wet wipes takes place is a question many businesses have intention to enter this market. Accordingly, cold wipes are produced on modern and advanced lines to meet the best quality standards and requirements. The following article will share details about materials, and machines as well as the most optimal immediate steps.

Learn more: DHTI – The leading & trusted wet wipes factory in the market

1. Materials to be prepared to produce cold wipes

1.1. Fabric – The most important raw material in the production of cold wipes

Fabric is the main ingredient in making cold wipes and wet tissues. The type of fabric commonly used in the production of cold wipes and wet wipes is a nonwoven fabric. Currently, on the market, there are many raw fiber materials used to make spunlaced nonwovens, and they are divided into groups, including natural fibers, man-made fibers, and synthetic fibers (chemical fibers).

| Type of yarn | Origin | Popular fabrics |

| Natural fiber

is |

woven from fibers available in nature with origins from:

|

|

| Natural man-made fibers | are man-made fibers through chemical synthesis, as opposed to natural fibers that are woven directly from plants and animals available in nature.

Made from cellulose polymers found in high cellulose-containing plants such as cotton, hemp, wood and flax. |

|

| Chemical fiber | is produced from chemical raw materials obtained from coal, gas, petroleum, … through complex transformation processes such as coal distillation, petroleum cracking, polymer synthesis. ,… After completing this whole process will create synthetic fiber fabric. | There are 5 main groups that are most common:

|

Which, the popular fibers for making non-woven fabrics are: Cotton, viscose/rayon, polyester, and polypropylene. Cotton or viscose/rayon are all ingredients made from natural fibers. They are characterized by good absorbency and are safe and benign for even sensitive skin. Polyester and polypropylene are essential “plastic” fibers. They are made from chemical synthesis, so they are durable (wipe surfaces well), but the ability to absorb sweat is poor, and the fabric is somewhat rough, less sooth, and capable of causing skin allergies.

Thus, the higher the percentage of natural fibers in non-woven fabrics, the safer and more benign it is for the skin. You need to pay attention to this to choose the right wet and cold wipes fabric for your needs.

| Needs Characteristics | Choosing | Choose a non-woven fabric with a yarn ratio |

| Surface cleaning | Preferably use fabrics with a certain absorbency and wipe ability as well as a certain thickness to be able to contact hard surfaces and remove stains, and bacteria from them | Balanced between natural fibers (cotton, rayon/viscose) and synthetic fibers (Polyester, polypropylene) |

| Baby wet wipes for facial skin | Absorbency and water retention fine, soft, thick, lint-free, thereby helping to gently clean without irritating the baby’s skin or sensitive skin areas such as the face The higher the ratio of natural fibers (cotton, rayon/viscose), the higher, the better | The higher the percentage of natural fibers (cotton, rayon/viscose) the better |

Read now: Wet facial tissues | Benefits & Tips to choose the right one for skin

In addition to the classification based on the origin of non-woven fabrics, to meet the different needs of users, non-woven fabrics are also classified based on Shape, including 2 types: Mesh fabric and marble fabric, specifically as follows:

| Fabric | Mesh fabric Balloon | |

| Features | The fabric is designed with an interwoven mesh surface with high breathability. | On the surface of the polka dots, when touching, there will be a slight friction feeling. |

| Uses | Sanitize hands, feet, and neck, … cool the body. | Clean face, hands, and neck, … wipe sweat, wipe stains. |

| Advantages |

|

|

| Limitations |

|

The cost is higher than the mesh core. |

| Who should use | Restaurants, restaurants, and small-scale coffee shops. | High-class restaurants and bars, 5-star hotels, and VIP karaoke bars. |

Discover more:

- Safe and popular antibacterial wipes today & How to choose the right one

- 4 safe & best quality unscented wipes & Guide to choose right product

- Top 4 safe alcohol free wipes, smooth skin care

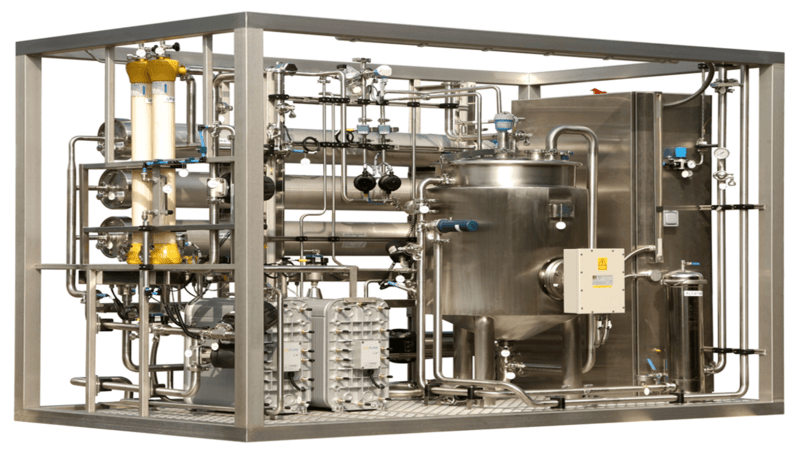

1.2. Water

To create a cold wipe, it is definitely indispensable to wet the wipes. When manufacturing cold wipes, water accounts for over 90%, the rest is some other active ingredients. At the same time, water acts as a solvent to help mix substances, keeping the tissue moist. To ensure quality and safety, water needs to be passed through water filtration systems to remove impurities and harmful bacteria. Currently, manufacturers often use RO water filtration systems (reverse osmosis technology) to filter petite sizes mechanically (<0.001 micrometers), thus filtering up to 98 – 99.8% of the components. in water include most impurities, metals, organic substances, bacteria, and viruses. This type of water is considered to be very safe and benign for the skin.

However, after RO filtration water system, 0.2 – 2.0% of single ions are still very small in size. Therefore, some advanced and high-quality manufacturers also filter water once again with the EDI water purification system – the world’s leading modern water purification technology. The EDI filter system works with the mechanism of using electric currents to exchange and dialysis impurity ions out of the water source. The outstanding feature of EDI water purification technology is that it does not need to use chemicals such as acid and caustic soda to regenerate. Filtered water has a safe pH of about 4.5 – 5.5. Thanks to that, the nutrients in the wet towel are easily absorbed and increase the effectiveness of skin care. The finished water created is ultimately 99.9% “ultra-pure” water, safe and gentle on even super-sensitive skin like a baby’s. If you have a need to produce wet and cold towels for babies, you should prioritize using EDI water to ensure the best quality for consumers.

With the desire to bring the safest and highest quality wet and cold wipes, DHTI is one of the few manufacturing companies that has used EDI technology – advanced water purification technology to bring friendly, suitable products. Suitable for all skin types, especially baby’s sensitive skin.

Read more:

- Safe and effective Luck Lady makeup remover wipes

- Mamamy premium wet wipes – Actively prevent diaper rash, take care of every nook and cranny

1.3. Other active ingredients

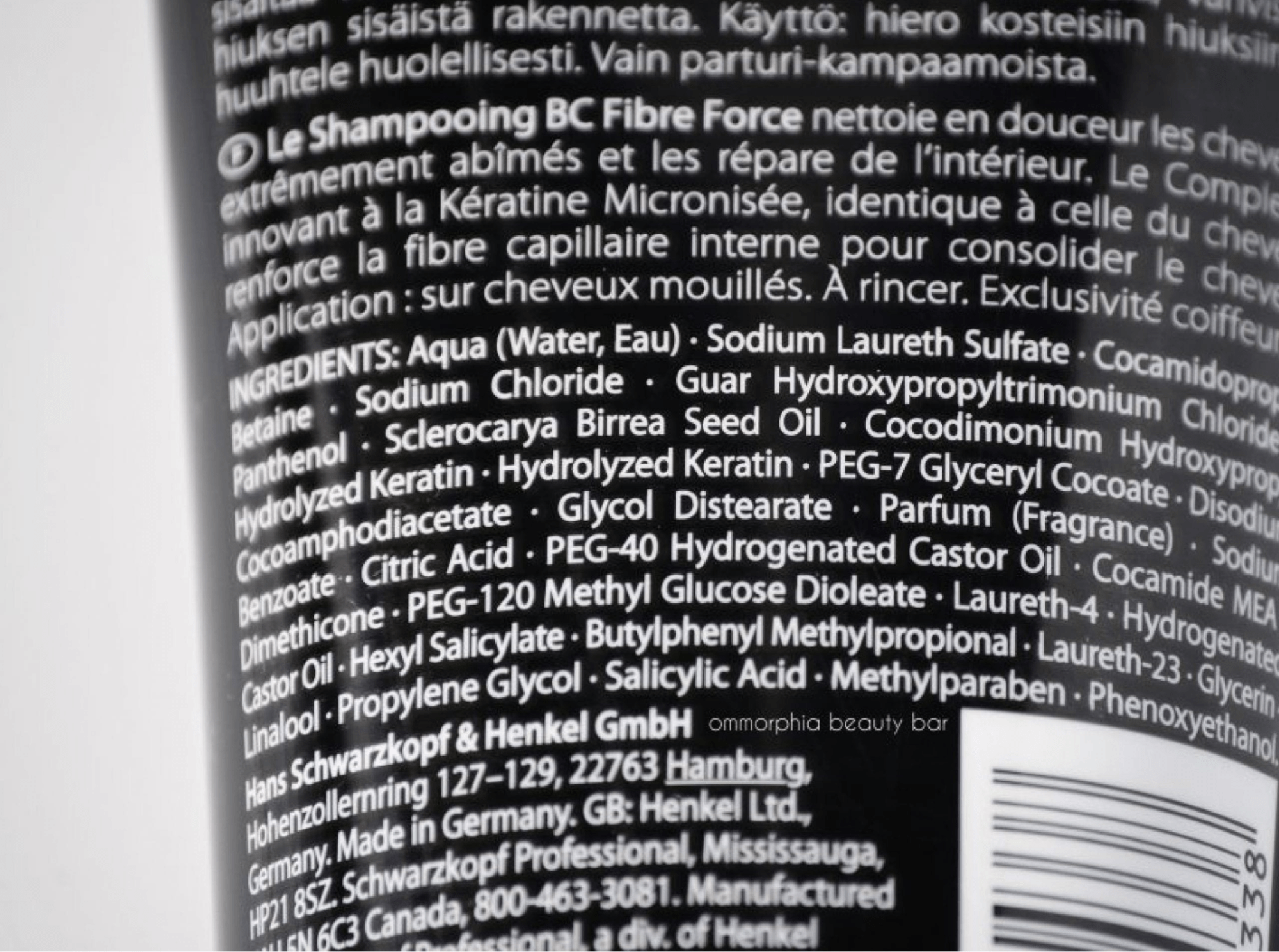

Other active ingredients commonly found in wet wipes and cold wipes are: Preservatives, antibacterial active ingredients, and moisturizing active ingredients.

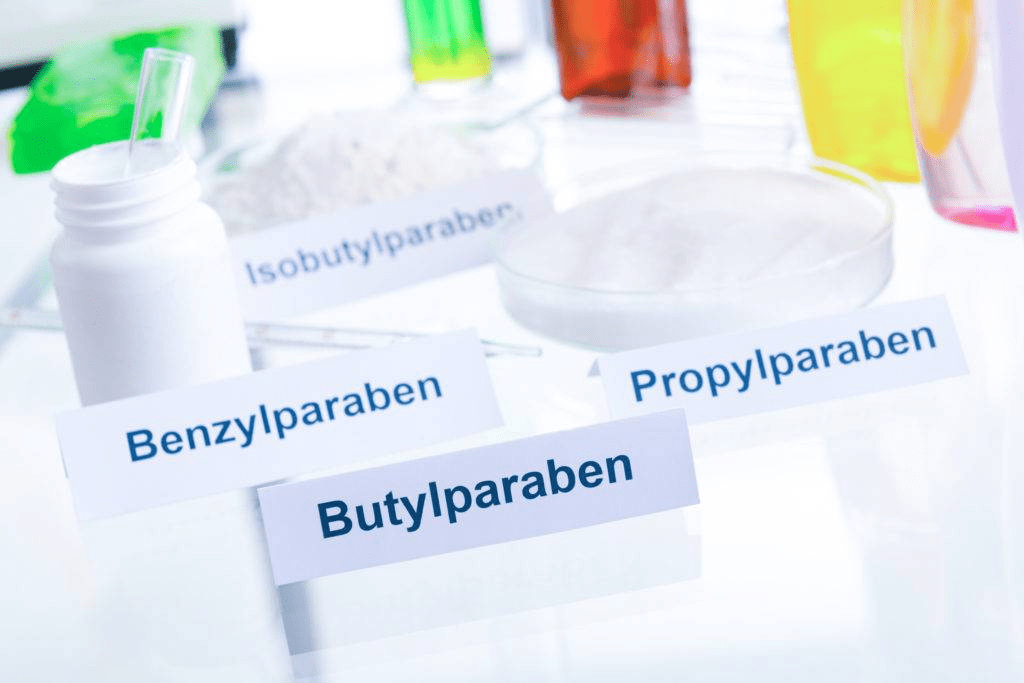

1.3.1 Preservative (antibacterial active ingredient):

The preservative is a necessary ingredient in all wet wipes or cold wipes in order to limit and eliminate dirty fungi and harmful microorganisms, thereby helping to prolong the life and quality of the product.

Common preservatives in wet wipes and cold wipes are: Paraben, Phenoxyl Ethanol, Benzoyl Peroxide, Methyl Parapen, Formaldehyde, MIT/MIC (Methylisothiazolinone/Methylchlorothiazolinone), Potassium Sorbate, Sodium Benzoate, Chlorhexidine Gluconate Solution…

Watch out: 9 harmful ingredients in wet wipes & Label reading guide (latest updated)

To ensure the safety of users, you should not choose chemicals that have been banned in the world such as: Parabens, Formaldehyde, and methylisothiazolinone (MIT),…

In addition to antibacterial agents (also known as preservatives above), currently, Manufacturers cold wipes production and wet wipes also add antibacterial active ingredients with other specialized uses such as anti-rashes, anti-heat rash (for example, Coco phosphatidyl PG-Dimonium Chloride,…).

Relevant post: Luck Lady Tea Tree acne wipes are safe for skin

1.3.2 Moisturizing active ingredients:

These ingredients can be added to wet wipes, cold wipes with the effect of moisturizing, softening the skin, and making the skin soft and comfortable. Elements Common in cosmetics in general and wet wipes and cold wipes, in particular, include: Hyaluronic acid, Butylene glycol, Caprylyl Glycol, Polyethylnene glycol, Propylene glycol, Lactic Acid, Stearyldimoniumhydroxypropyl Laurylglucosides Chloride,…aloe (Aloe vera), Inca Inchi essential oil, castor oil, cocoa butter, shea,…

You should choose moisturizing ingredients and active ingredients of natural origin or synthesized from nature such as: Stearyldimoniumhydroxypropyl Laurylglucosides Chloride, Aloe Vera, Inca Inchi Essential Oil, Castor Oil, Glycerin… Avoid using moisturizers synthesized from petroleum processing because they have the potential to cause allergies, Itchiness is higher than that of natural moisturizers. Some moisturizers have controversial levels of safety and are benign to the skin, such as: Propylene glycol, Butylene Glycol,… Before buying a product with moisturizing active ingredients, check the ingredient list for protection. your skin.

In addition, the manufacturer also adds flavorings. This is the ingredient that makes cold towels smell nice and easily attract towel users. Furthermore, this ingredient aids in the removal of unwanted scents from the manufacturing process – their original smell is quite pungent and offensive to the user.

Fragrances used in most cosmetics and cold wipes and wet wipes include 2 types: natural flavorings and synthetic fragrances:

- Natural flavorings: are fragrances produced from plants and animals that have been undergone animals. physical, microbiological, and enzymatic processes. This flavoring can be used immediately in its natural state or processed for use.

- Chemical flavoring: a type of flavoring that is synthesized from substances not available in nature (crude oil, coal tar,…) or a combination of natural spices and some substances to create spices. new.

In fact, to ensure the safest and most benign for the skin, you should use unscented products. In case you want to use scented wet or cold wipes, you should give preference to products with natural fragrances because they are less likely to cause skin irritation or related skin problems. In particular, if you have sensitive skin, you should use sample products or small packages to test how your skin reacts to the product.

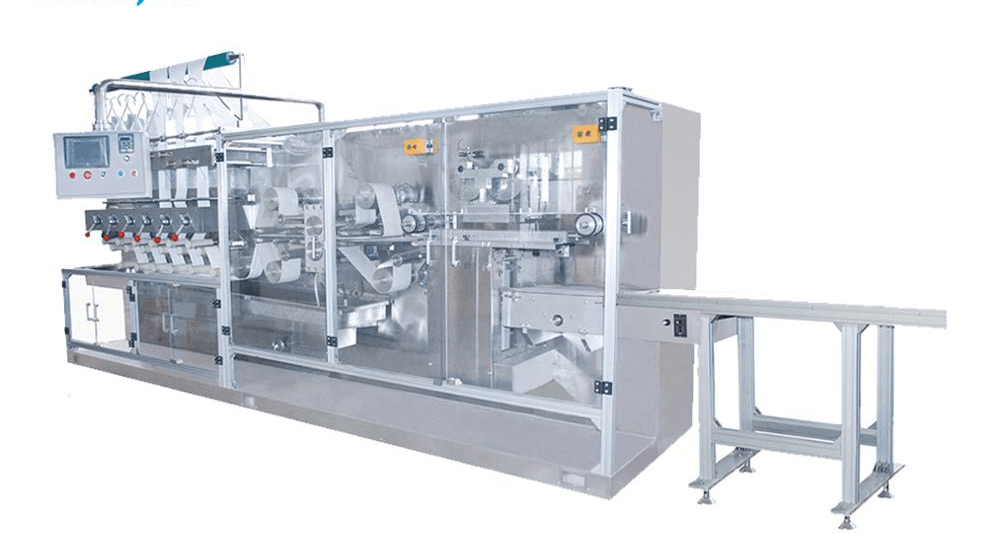

2. Current production line of cold wipes and wet tissues

For cold wipes production or wet wipes, owning all kinds of machines is a must. Currently, on the market, there are many types of machines with different capacities and designs. Typically wet tissue and cold wipes production machines are divided into three types: mini machines, semi-automatic production machines, and automatic machines. fully moving.

Learn more: Wet wipes manufacturing cost | Price of each machine

From the perspective of a manufacturer or business that orders cold wipes production and wet wipes, you need to pay attention to choosing a wire. The right production line is based on the following factors: Production scale, capacity, automation level (level of human involvement in the production process), product success rate, and available cost willing to invest in cold wipes production line. Below is a detailed analysis of the above 3 machine categories:

| Mini machines | Vending machine | Fully automatic machines | |

| Production scale | Small order, small quantity | Suitable for medium or large-scale production workshops. | Ideal for businesses that need to produce cold wipes in large quantities. |

| Capacity | 25 pcs/min | 30 – 120 pcs/min | 200 – 300 pcs/min |

| Automatic level Automatic | and requires 1 person to operate. | Some operations are manual, so it takes time and money to hire workers. | The production process of wet wipes and cold wipes is fully automated by machines, saving labor (people only participate in the role of checking the quality of output products). |

| Output product success rate | Relative output product quality, many cases of low quality products | High-quality products, few defective products. | Product quality is high, and uniform, very few defects. |

| Price | 7,000,000 VND – 10,000,000 VND | 79,000,000 VND – 110,000,000 VND (depending on the type) | 100,000,000 VND – 3,500,000,000 VND |

Thus, the above analysis has given the necessary information for you to Select the appropriate wet tissue production line, cold wipes production line. If you are in need of becoming a wet wipes manufacturer, you are looking for a production line for cold wipes and wet wipes to meet a large demand for customers, or you are a wet wipes business and want to own a production line. For your own production, you should choose fully automatic or semi-automatic machines because these machines have high durability and produce good quality products in the shortest time.

In case you do not have enough resources to invest in self-production, but you still want to have wet wipes branded with your business, you should choose a factory with a modern and good production line of cold wipes and wet wipes. Especially owning a fully automatic line. The advantage of the 100% automatic line is that the machine’s capacity is large, thus helping to shorten the production time, which means that you will quickly get the desired amount of products in a certain time. In particular, this machine line always ensures good output product quality.

Discover more:

- OEM wet wipes method – All things wholesalers need to know

- ODM wet wipes | Vietnam’s leading wet wipes outsourcing company

3. The “optimal” 5-step process for standard wet and cold wipes production at DHTI

DHTI is certified with Quality Management System. Quality ISO 9001: 2015 – the latest version of ISO 9001, is one of the prestigious certifications that every manufacturer wants to have. Therefore, customers are always assured to order production because product quality is always guaranteed.

The production of cold wipes production and wet wipes need to ensure proper technical and occupational safety, high productivity and quality finished products according to the manufacturer’s standards. steps below:

3.1. Step 1: Prepare materials & ensure the production environment

1 – Prepare production materials

Each production batch we have its own requirements sheet and specifications. The shift leader will receive orders and production requests from specialists.

Next, the controller collects raw materials from the warehouse keeper and checks the quality of the materials. After checking, all information must be recorded in the previously printed request sheet. This helps all information to be controlled accurately and easily saved, management or customers can completely check production batch information at any time.

When the material meets the quality and production requirements, workers will clean the fabric roll and membranes before being put into production.

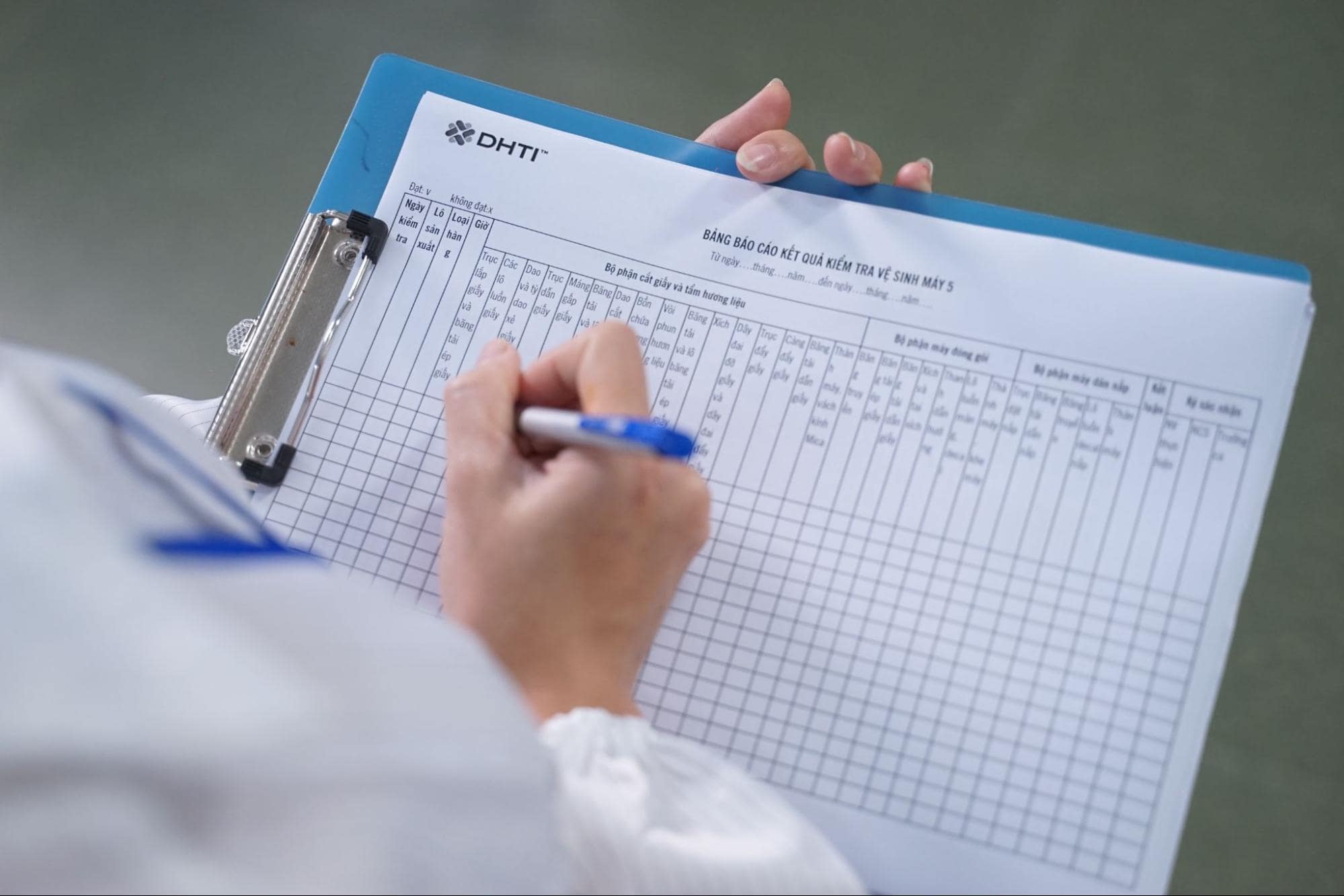

2 – Ensure the production environment

We test and make sure the production environment is sterile (this is a condition that, normally, only factory production can meet) – is the environment there does not exist any harmful bacteria, fungi and potentially affecting product quality. With us, a product can only guarantee its commitment to quality when every small step in the production process of cold wipes and wet wipes is strictly inspected and controlled by the hygiene.

Before every production session, we start with disinfection, including: disinfecting machines and all employees involved in the production process. export. Accordingly, each worker is wearing protective gear and disinfecting with industrial alcohol. With machines, each type will have its own characteristics, and we have a separate standard evaluation table for each machine. The controller conducts tests according to each criterion and records the results. This helps our quality control to be strict, accurate, and effective. Partners, when working with us can also track the entire quality control process of each production batch through these records.

DHTI uses today’s leading cold wipes and wet wipes production technology with a 100% automatic production line. Before starting the machine, the worker installs the fabric roll on the fabric mounting shaft and then installs the film on the membrane mounting shaft.

After checking the materials, the worker starts the machine and sets the product parameters:

- Fabric cutting size.

- Packaging size.

- Amount of water used to marinate the product.

- Determine the cut-off size.

- Set Production Date and Expiry Date.

With printers and packaging machines, workers perform the steps of installing films, decals, and auxiliary stamps (if any) on the shaft and proceed to install the machine: Setting product parameters: Position of film, decal

- … according to the specifications for the product.

- Press the confirmation button to receive data to determine the cut size.

- Turn on the power switch for NSX and HSD printers – NSX and HSD settings – select inkjet print mode – select the production type included in the machine’s data according to the work order.

- Check product quality after packaging (package has any problem or not, cap / sticker is deviated or not).

When checking and finding that the quality of the cold wipes production line is stable, adjust the machine to run in drift mode, the maximum speed does not exceed 285.

DHTI uses a fully automatic wet tissue and cold wipes production line, so as soon as the machine is started, the entire process of cold wipes production will be processed by the machine. Workers are responsible for monitoring throughout the production process to ensure that there are no errors or to make timely corrections.

3.2 Step 2: Making active ingredient phase

After the fabrics are folded by machine, they will be moved to the next stage, which is to wet the active ingredients including purified water (EDI water), antibacterial active ingredients, nutrients, moisture, and aroma. In, depending on the production requirements, moisturizing active ingredients and fragrances are added or not.

Next, the fabric will be taken to the cutting box.

3.3 Step 3: Cut fabric The

wetted fabric is further folded and cut to the adjusted size on the machine. After cutting the fabric, they will be folded in half and transferred to the packing stage.

3.4 Step 4: Packing & gluing

After the machine automates the steps from packing, the product will be transferred to the final runway for workers to check product quality and packaging (products are forwarded to the packing action with lidded shipments).

3.5 Step 5: Check product quality and packing

In this step, workers collect sample products, each production batch will be randomly taken a few samples for testing. Quality assurance products will be delivered to customers, in case the sample product has problems, it will be immediately recalled.

Workers check whether the output products are satisfactory or not:

- Check and remove torn products, defective printed film.

- Re-calibrate the paper cut-out size, packaging size, and fabric fold if the product is unsatisfactory.

- Check the weight of each package.

- Check the head, tail, and back welds of the product.

- Check the grip of NSX and HSD.

- Check the vapor level of the product.

The approved batches of products will be packed according to the required quantity and specifications. Then, DHTI proceeds to send the products to the partner’s warehouse or point of sale.

After the above steps are fully automated, the product is created with high quality assurance, the packaging is firmly packed and the print quality is almost absolute sharp by DHTI using a printing system. Gravure – one of the leading printing technologies today.

In case your business needs to order production, please contact DHTI to receive a free consultation on wet wipes production, especially all of our customers and partners are invited by us to LIVE VISIT to understand clearly understand each process and our care and thoroughness in each stage. Here are the reasons DHTI is your TOP choice:

4. Why order wet and cold wipes at DHTI?

4.1 Experienced R&D team to help offer maximum benefits for partners

Established in 1999, up to now, DHTI has more than 23 years of experience in manufacturing cold wipes and wet wipes, successfully implementing thousands of large and small projects at home and abroad. We understand, in order for cold wipes to best serve each customer, what elements and ingredients are needed. Therefore, when you submit a processing request, our team of experts will work with you to analyze and evaluate to choose the fabric material, the best active ingredients to put in to create a conveyable product. brand spirit of your business. Parallel to the problem of optimizing resources for you.

With the principle: “Do not use ingredients that have been banned in the world, although not banned in Vietnam,” because there is a possibility. harmful to the health of users, when you hand over your brand to us, you don’t need to worry about product quality. For the same purpose of choosing preservatives in wet and cold wipes, you can use many different ingredients such as Paraben, Methanol, Formaldehyde, Methylchloroisothiazolinone (MIC) /Methylisothiazolinone (MI), Sodium Benzoate,… In fact, Paraben or MI/MIC ingredients have been banned in the world, but not banned in Vietnam, DHTI mainly We do not use this component to ensure the safety of our customers.

Therefore, you just need to focus all your energy on increasing sales, managing your business, and producing quality products, and let them I undertake.

4.2 DHTI has the ability to create trend-leading products that help partners easily compete and stand out in the market

The spirit of “Best & Better” is the guideline throughout all activities of DHTI, we I constantly strive to create new products that are always better than the previous one. Not only are we a manufacturer, we also have our own brands of wet wipes that are already established in the market – such as the Mamamy baby wipes line.

Since its inception in 2007, Mamamy is the first line of unscented wet wipes in Vietnam, and one of the few wet wipe brands using US-patented antibacterial ingredients, supporting parents to be proactive. Prevent diaper rash, effectively prevent heat rash for babies. Not stopping there, in 2022, DHTI launched Mamamy Tropical – the FIRST NATURAL wet wipes in Vietnam. This is a breakthrough and “revolutionary” product line in the wet wipes industry with 100% natural fibers. Furthermore, Mamamy Tropical wet wipes are also one of the few wet wipe brands that use tropical natural ingredients (such as marigold essential oil, inca inchi essential oil, …) to care for babies. tropical country.

Thus, as long as you have the desire to own the breakthrough wet and cold wipes product lines, becoming a main product in your business’ product portfolio, please share your ideas and wishes with us, we will work with you to realize them.

4.3 DHTI successfully exported alcohol wipes to the US market

In 2020, DHTI officially exported the Luck Lady alcohol wipes to the US market – one of the most demanding markets globally. After this outstanding event, DHTI received many offers to order cold wipes and wet wipes, which greatly increased the number of production orders.

This proves that products made by DHTI not only meet domestic requirements and standards well, but also adapt and meet all standards very well. the strictest and most demanding standards of the international market.

4.4. Diverse product models, helping to elevate and spread the brand

With a creative design team, we support businesses to own eye-catching, impressive product packaging and well express the brand spirit, making it easy for customers to remember and sympathize with.

In addition, DHTI owns a modern printing and production system of wet and cold towels, especially 100% automatic, capable of accurately printing colors and maintaining high product durability.

4.5 Successful partners and projects of DHTI

During more than 23 years of manufacturing and distributing wet wipes, and cold wipes, DHTI has received a lot of trust from partners in many different fields:

- Cold wipes partners: Gio Bien restaurant – hotel, Korean K-BBQ buffet restaurant, Van Anh luxury garage, …

- Big wet wipes partners:

- Mother and baby stores: Kidsplaza, Bibo Mart, Con Cung,…

- Retail store system: Green Department, Liberico,…

- International Aesthetic Hospital: Dr. Hana.

DHTI is also a manufacturer of cold wipes, OEM wet wipes for international partners, especially in countries such as the US, Taiwan,

Besides the trust from production partners. Exporting wet wipes and cold wipes, DHTI is also a reputable distributor of wet wipes and cold wipes throughout Vietnam, with

16,000 retail points. So, when you order from DHTI, you can get quality products, impressive designs and the ability to sell with high sales.

Thus, the products produced by DHTI always prove attractive to the market. In addition, DHTI always has preferential programs for partners who order the production of wet and cold towels. If you want to own a high-quality, outstanding and brand-name wet and cold towel product, please contact us for a free consultation:

Address :

- Representative office: 69B Thuy Khue, Thuy Khue Ward, Tay Ho District, Hanoi City.

- Factory address: Lot CN7, Tu Liem Industrial Cluster, Minh Khai Ward, Bac Tu Liem District, Hanoi.

Website DHTI: https://dhti.vn/en/

Hotline: (84-24).3716.0270

Above, we have summarized the specific steps in cold wipes production for you to better understand each step of creating wipes products. wet paper, cold wipes best quality. We always believe that each product delivered to consumers not only affirms the interest from your business but also a commitment to quality and prestige.